WhatsApp

WhatsApp

Henan Doing Environmental Protection Technology Co., Ltd

Development status of dry copper wire recycling machine

With the development of social economy, the contradiction between copper production and consumption has become increasingly prominent. As a renewable resource, the waste cable can not only alleviate the lack of copper ore resources in China, but also meet the current national requirements for energy conservation and environmental protection. DOING company outlines the production process and development trend of copper wire recycling machine and classification of waste copper wires.

Copper wire recycling machine and the separated copper & plastic

Most small and medium-sized enterprises still use traditional processing equipment to recycle waste cables, such as burning copper or washing copper. The traditional separation process and technical resource utilization rate is low, and waste gas, waste water and waste residue will be generated, and environmental problems are also excellent. In recent years, the dry copper rice machine has occupied a dominant position in the market, because it fully meets the characteristics of high efficiency, no pollution, and meets national environmental protection requirements.

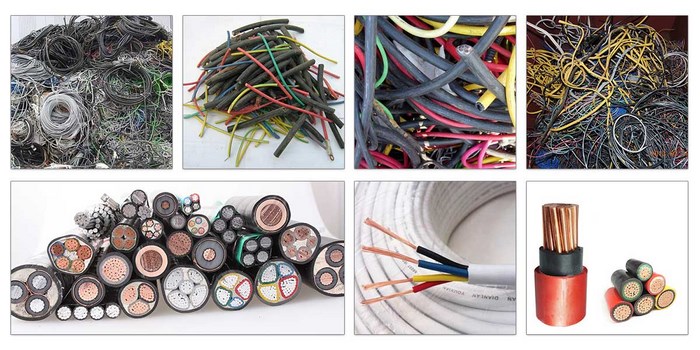

Different kinds of waste cable wires

Different kinds of waste cable wires

The application range of dry copper wire recycling machine is wide. Dry copper wire recycling machine can not only process thick square wires and cables, but also raw materials such as automobile wires, motorcycle wires, electric vehicle wires, network wires, communication wires, household appliance dismantling wires, and electronic wires. The peeling equipment has a higher output, which greatly reduces the manual work intensity.

Dry copper wire recycling machine

Dry copper wire recycling machine

The production process of dry copper wire recycling machine is environmentally friendly and pollution-free. The dry copper wire recycling machine uses physical sorting technology, which is first crushed and then crushed. After crushing, air separation and electrostatic separation technology are used to completely separate copper and plastic. The separated copper and plastic particles are discharged from different outlets. The air separation and electrostatic separation equipment are used together, and the purity of copper and plastic can reach more than 99%.

The dry copper wire recycling machine provides a wide development space for copper scrap recycling. In terms of resource reuse, Brings huge economic and social benefits.

hot selling equipment

Leave Message

If you want to get more details about Development status of dry copper wire recycling machine, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.