WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

To recycle radiators to get copper and aluminum out, you can use the following three methods:

Methods of recycling radiator

Methods of recycling radiator

1. Peeling copper and aluminum by hands

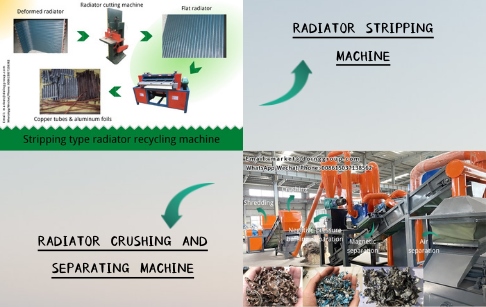

2. Separating radiators by radiator stripping machine to get copper and aluminum out

3. Using copper aluminum radiator recycling production line, to get copper and aluminum after crushing and being separated.

But which kind of method do you want to use? You can choose suitable one based on your situation. Next, DOING will introduce them for you one by one.

It is no need to invest more to use this method, but it is very difficult to process large quantities of waste radiators. And it can only to process single air conditioner radiators to get copper and aluminum. If you also have double or multi-layer radiators and car water tanks, it is impossible to separate copper from aluminum. So this method gradually is not use.

As the above video shows, the radiator stripping machine can easily separate radiators to get copper tubes and aluminum foil. If your radiators is multi-layer, the radiator cutter machine can cut the radiators into single-layer, and also can cut iron edge off on the radiators.

This set of radiator stripping machine and radiator cutter machine is easy to operate and occupy small land, but it can not be used to process car water tanks and industrial condenser. If you have these two kinds of radiators, you can use the third method.

Copper aluminum radiator recycling production line can process all kinds of radiators, which adopts dry type crushing and separating method to process radiators into pure copper, aluminum and iron. The separation rate of this machine is above 99%. The working process is as the following video shows:

The whole working process is divided into three steps: shredding, crushing and separating. There is negative pressure folding separator which will separate light aluminum first. Before copper and iron and heave aluminum through belt conveyor into air separator, there is magnetic separator sort iron out of mixed metals. At last, air separator will separator copper and heave aluminum.Finally, you will get pure copper and aluminum and iron.

Which method do you think is the best? If you want to start waste radiators recycling business, please contact us for free quotation!