WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

There are two main types of machines used when recycling waste radiators - radiator stripping machine and radiator crushed and separation machine. Radiator stripping machine and radiator crushed and separation machine each have their own characteristics and applicable scenarios. When choosing, it is necessary to comprehensively consider the raw materials, equipment technology, processing volume and budget.

Radiator stripping machine

Radiator stripping machine

Radiator stripping machine is mainly used for relatively intact or relatively small damaged waste air conditioners or car radiators. Radiator stripping machine can directly strip the aluminum foil off the copper tubes, and keep the shape of the aluminum foil. Generally, it can process single-layer and double-layer radiators with copper tube spacing of 19mm, 21mm, and 25mm. Extra-wide radiators and multi-layer radiators can be pre-processed with a radiator cutting machine.

Radiator crushed and separation machine

Radiator crushed and separation machine

However, radiator crushed and separation machine is suitable for processing a wider range of waste materials, including radiators that are damaged, twisted or difficult to peel manually. Through the crushing process, radiators in various states can be processed, and copper and aluminum can be effectively separated through subsequent separation technologies (such as air separation, magnetic separation, etc.). The final products obtained after separation are mostly granules, which are convenient for further processing and transportation.

Radiator stripping machine has a relatively simple technology, compact design and small footprint. It strips the aluminum foil from the copper tube of the radiator through physical methods such as extrusion and cutting. The specific process is shown in the video.

The processing volume of the radiator stripping machine is 300-400, 400-500kg/h. It is very easy to operate and more suitable for household recycling with less processing volume.

Radiator crushed and separation machine

Radiator crushed and separation machine

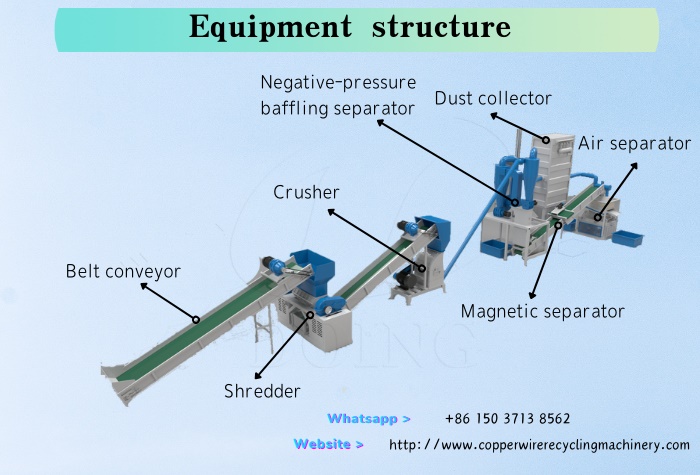

The radiator crushed and separation machine uses more complex crushing and sorting technology, which can automatically complete the whole process from crushing to separation, and is suitable for large-scale industrial production. The processing capacity of the radiator recycling and separation machine is 500kg/h, 1000kg/h, and 2000kg/h, ect. Its process includes multiple steps such as shredding, crushing, magnetic separation and air separation, which can efficiently process a large amount of waste radiators, but the equipment cost is relatively high.

The radiator stripping machine is relatively simple in structure and technology, and the initial investment cost is relatively low. It is suitable for small recycling stations or personal use, and is economical for processing a small amount of high-quality waste.

Radiator recycling machine

Radiator recycling machine

Although the initial investment of radiator crushed and separation machine is large, it is suitable for medium and large recycling companies due to its high efficiency and large-scale processing capacity. In the long run, the unit processing cost may be lower, especially when there is a stable and large source of waste radiators, and its return on investment is higher.

If you focus on processing a small number of or relatively complete radiators, and have high requirements for the integrity of copper and aluminum materials, and have a limited budget, then the radiator stripping machine may be a better choice.

For customers who need to process a large number of complex or damaged radiators, pursue high efficiency and large-scale production capacity, and do not mind the higher initial investment, the radiator crushed and separation machine is more suitable. It can provide higher processing volume and automation level, suitable for large-scale operations.

Henan DOING Company has focused on waste recycling machines for more than fourteen years and has a team of high-quality engineers. No matter which of the two equipment you choose, we can provide it to you with high-quality equipment and preferential factory prices. If you are interested and want more details, please contact us.