WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

The demand for high-quality biochar is surging, thanks to its key role in sustainable agriculture (soil improvement, carbon sequestration), renewable energy and advanced filtration technology. For companies ready to take advantage of this growth opportunity, efficient and sustainable production scale is essential.

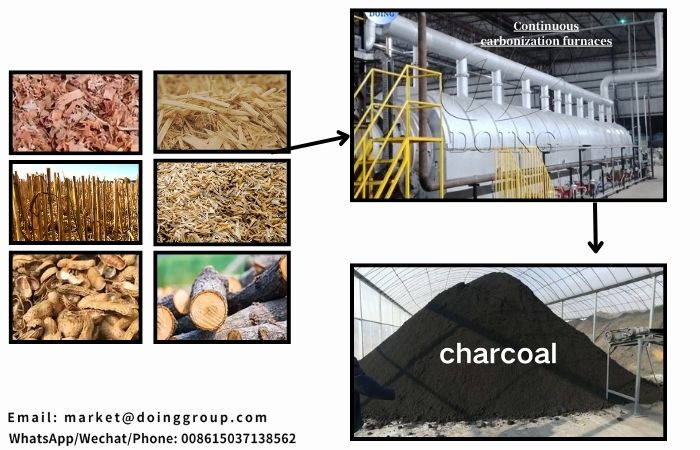

Biochar is a solid product formed by heating biomass in the absence of oxygen through pyrolysis technology. This process not only retains the carbon element in the raw material, but also forms a porous structure, which gives biochar good adsorption properties and water holding capacity. Common raw materials that can be used to produce biochar include various organic wastes such as wood chips, crop straw, fruit shells, livestock and poultry manure, etc.

Biomass to biochar via pyrolysis technology

Biomass to biochar via pyrolysis technology

Earth kilns and brick kilns are more traditional biochar production machine, suitable for small-scale production. This type of equipment has a low investment cost, but the production efficiency is not high, the thermal energy utilization rate during the production process is low, and the operator's experience requirements are high. Traditional methods often fail to meet the needs of large-scale continuous production of biochar, with low output, unstable quality, and huge impact on the environment.

DOING biochar carbonization reactor is designed for continuous operation and can quickly process large amounts of biomass. Automatic feeding of raw materials and continuous output of biochar enable true industrial-scale output to meet growing market demand. The biochar produced has a stable yield, usually exceeding 30%, which is much higher than traditional kilns or basic distiller. For users with higher daily output requirements, continuous pyrolysis machine is a more suitable choice.

Automatic continuous biomass feeding system

Automatic continuous biomass feeding system

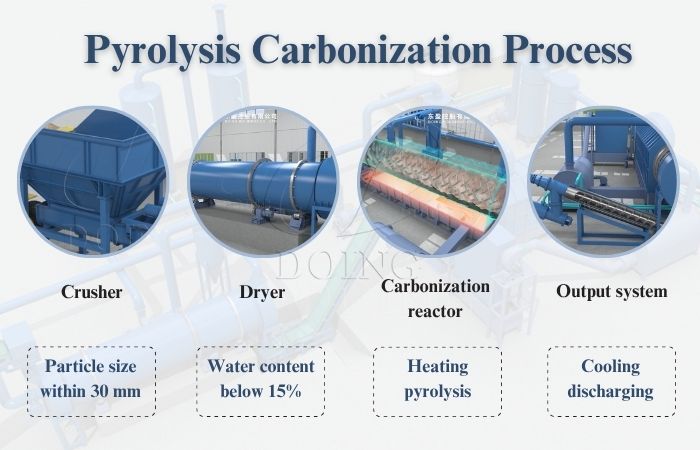

To achieve efficient production of biochar, in addition to choosing the right machine, the optimization of the production process cannot be ignored:

Appropriate crushing and drying can improve pyrolysis efficiency and improve the quality of biochar. To help customers carbonize and produce more efficiently, DOING provides crushers and dryers to pretreat biomass raw materials. By crushing the biomass raw materials, it is ensured that they are evenly heated and efficiently carbonized, and after drying, the raw materials can be pyrolyzed more efficiently to obtain higher quality biochar.

Biomass pretreatment and biochar production process

Biomass pretreatment and biochar production process

Precise temperature control can produce biochar products that meet the requirements of specific uses. DOING continuous biochar reactor uses precise temperature control and pyrolysis process control-heating biomass in an oxygen-deficient environment. This optimized process maximizes the conversion of raw biomass into high-quality biochar.

In addition to biochar, pyrolysis also produces syngas and wood vinegar. The combustible gas and liquid products produced can be recycled to reduce overall production costs. DOING biochar reactor system can efficiently capture and recycle these valuable byproducts. Through the heat recovery unit, the synthesis gas is recovered as fuel for the pyrolysis process or for drying the raw materials, thus significantly reducing the need for external energy. The wood vinegar can be collected for agricultural or industrial use.

Biomass pyrolysis byproducts recycling and reuse

Biomass pyrolysis byproducts recycling and reuse

DOING's biochar reactors are designed for large-scale, efficient biochar production while ensuring environmentally friendly production. Our machine is equipped with advanced exhaust gas treatment systems (scrubbers, condensers) to capture and neutralize pollutants before they are discharged. This integrated approach combines efficient carbonization with emission control and by-product utilization, significantly reducing the overall environmental footprint of large-scale biochar production and meeting global sustainable development standards.

We have decades of experience in designing and manufacturing reliable biomass pyrolysis machine for customers around the world. Continuous innovation in biochar carbonization reactor design and process control to achieve optimal large-scale biochar production. From initial consultation and plant design to equipment supply, installation support commissioning, and subsequent maintenance, we provide you with services throughout the process.

If you are considering investing in a large scale biochar production project, or need to upgrade your existing biochar production equipment, please contact DOING today!