WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

The installation of solar panel recycling equipment in India is a systematic project,involving equipment selection,equipment transportation, on-site assembly, commissioning and operation, etc. In the Indian market, due to the particularity of climatic conditions, infrastructure and regulatory environment, the installation process requires more detailed planning. As a professional solar panel recycling equipment manufacturer, DOING will explain to you in detail the steps to install a solar panel recycling machine in India.

When selecting a solar panel recycling machine for the Indian market, three critical factors must be evaluated: processing capacity, material adaptability, and operational stability. The hourly throughput should match both current waste volumes and projected growth. And the system of machine must can handle diverse panel types - particularly India prevalent polycrystalline modules and thin-film panels. Crucially, operational stability requires robust power conditioning and climate-resistant components to withstand India extreme temperatures and high humidity, ensuring consistent performance through monsoon seasons and power fluctuations. DOING equipment can process all types of waste photovoltaic panels, and has powerful power conditioning devices and stable weather-resistant components. We have equipment with a processing capacity of 500kg per hour and 1000kg per hour. If you need equipment with a larger or smaller processing capacity, we can also provide customized services according to your needs.

Solar panel raw materials,products and recycling equipment

Solar panel raw materials,products and recycling equipment

Since solar panel recycling machine is usually large and contains precision components such as crushers and sorters, it is necessary to ensure shock-proof and moisture-proof packaging during transportation. In India, port customs clearance may involve additional documents such as the import/export registration code (IEC) and Goods and Services Tax (GST) number of the recipient party. It is recommended to cooperate with a logistics company familiar with India's import process in advance to avoid delays. With extensive experience in the Indian market, such as Gujarat, Tamil Nadu, and Maharashtra, DOING has demonstrated proven expertise in delivering turnkey solutions tailored to India's unique operational requirements. We offer comprehensive support covering customs clearance, localized installation and ongoing maintenance.For detailed proposals based on experience with installed solar panel recycling facilities in India, please contact our project team.

Solar panel recycling machine shipped to India

Solar panel recycling machine shipped to India

Before installing solar panel recycling equipment in India, you need to ensure that the site meets the load-bearing requirements and has a stable three-phase power supply. Due to the high temperature and dust in India, key components of the equipment require additional dust and heat dissipation design. If the site is located in a monsoon-affected area such as Mumbai and Chennai, drainage and moisture-proof measures must also be taken.

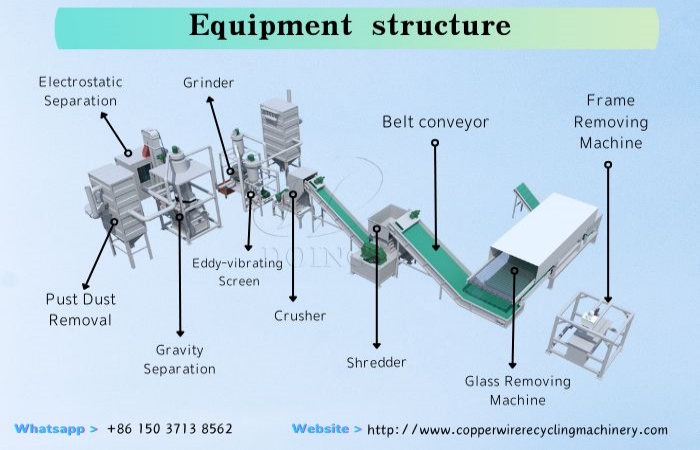

The installation sequence of the core equipment of the solar panel recycling machine is usually as follows: aluminum frame dismantling machine, glass removal machine, conveyor belt, double-shaft shredder, crusher, grinding machine with cooling system, eddy vibrating screen, air separator, electrostatic separator. In India, due to unstable power supply in some industrial areas, it is recommended to configure backup power supply for key equipment. Pay special attention to horizontal calibration during assembly to avoid reduced sorting accuracy due to uneven ground. DOING's engineers are experienced in installing equipment in India and can provide free on-site installation and commissioning services

DOING solar panel recycling equipment structure

DOING solar panel recycling equipment structure

Voltage fluctuations in the Indian power grid may affect the stability of the PLC and sensors of the equipment. The following tests need to be carried out step by step during the commissioning phase:

No-load operation: Check if there is any abnormal vibration in each component.

Material test: First test a small amount of waste solar panels and adjust the crushing size, sorting air flow speed and other parameters.

DOING professional technicians and engineer team

DOING professional technicians and engineer team

The above mentioned are the specific steps to install solar panel recycling equipment in India. In summary, if you want to set up a solar panel recycling machine production line in India, you need a professional manufacturer. As a professional manufacturer of solar panel recycling machine, DOING can not only provide dust-proof,moisture-proof and high temperature resistant designs that meet Indian conditions, but also assist in handling customs clearance, local certification and other problems. If you need to know more about the adaptability of the equipment or installation details, our engineering team can provide a full-process solution from site selection assessment, on-site installation and after-sales support, please feel free to contact us.