WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

As electric vehicles and consumer electronics gain widespread use, the volume of spent lithium batteries continues to soar. A critical question arises for businesses and investors: What percentage of lithium batteries are recycled? Currently, the global recycling percentage of lithium batteries hovers around 40% to 50%. This means nearly half of all used lithium batteries end up in landfills or are improperly disposed of, leading to valuable resource waste and environmental risks from toxic substances like lead and cadmium.

The low recycling percentage of lithium-ion batteries stems from a complex interplay of multiple factors. At the source, the comprehensive recycling system has yet to be established. Large quantities of waste batteries are scattered among consumers or discarded with ordinary waste, failing to enter proper recycling channels.

Secondly, limitations and outdated technologies in lithium battery recycling processes contribute to the problem: traditional pyrometallurgical recycling methods are energy-intensive and have low overall recovery rates for valuable metals, while manual operation increases costs and safety risks; although hydrometallurgical recycling yields high purity, it involves lengthy processes, consumes large amounts of chemical reagents, and requires stringent environmental treatment. The economic viability of recycling lithium iron phosphate batteries, in particular, is not significant.

Lithium-ion battery recycling methods

Lithium-ion battery recycling methods

Furthermore, relevant policies, regulations, and mandatory standards are still incomplete, the Extended Producer Responsibility (EPR) system has not been fully implemented, and there is a lack of close collaboration between upstream and downstream segments of the industry. The "battery production-use-recycling" closed loop is fragmented, and these factors collectively hinder the improvement of lithium-ion battery percentage.

To overcome this bottleneck, systematic strategy for improving lithium battery recycling percentage is essential.

The primary task is to build a convenient and efficient waste battery recycling network, combining online and offline methods, and supplemented by economic incentives such as deposit systems and trade-in programs, to truly solve the problem of "not being able to collect" used batteries.

A deeper solution lies in innovation in technology and recycling equipment. By developing and promoting intelligent lithium-ion battery crushing and sorting machine and low-carbon, high-efficiency recycling processes, processing costs can be significantly reduced, metal recovery rates and economic benefits can be improved, transforming recycling from a "burden" into a profitable business.

Battery crushing and sorting machine to improve lithium-ion battery recovery rate

Battery crushing and sorting machine to improve lithium-ion battery recovery rate

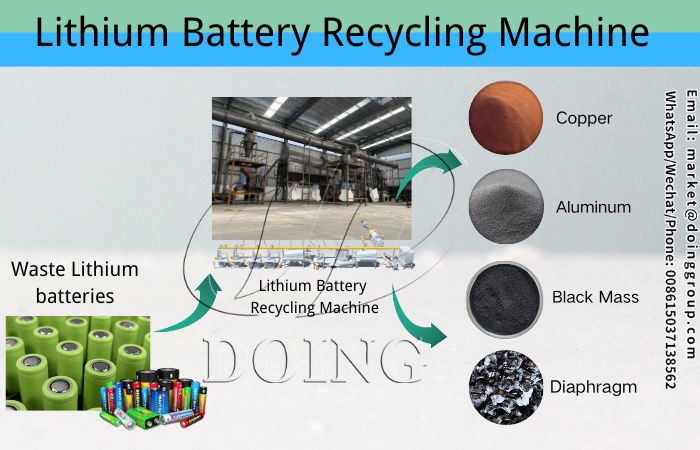

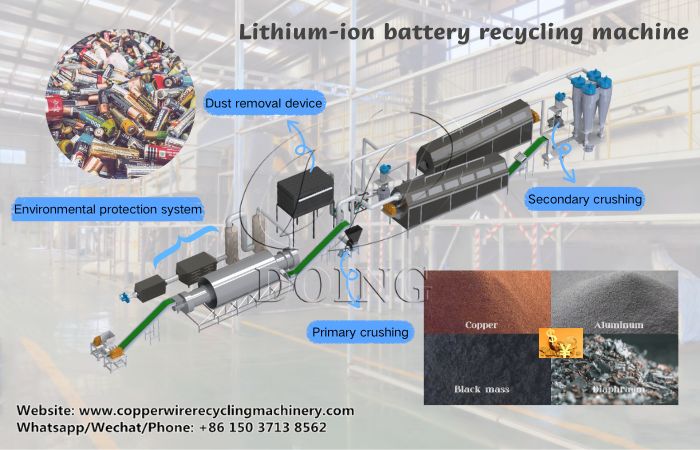

DOING's lithium battery recycling solution is designed precisely for this purpose – to increase lithium-ion battery recycling percentage and unlock the value of battery waste.

① DOING lithium battery recycling equipment utilizes multi-stage physical crushing and separation process, including safe discharge, shredding, crushing, magnetic separation, and precision screening, achieving material recovery rate of over 98%. This ensures high-purity copper, aluminum, and black powder containing lithium, cobalt, and nickel – materials that can be directly reintroduced into the manufacturing supply chain, creating stable revenue stream.

② Our equipment also offers practical advantages for long-term operation. It is fully controlled by a PLC intelligent system, requiring only 1-2 operators for continuous 24/7 operation, significantly reducing labor costs and minimizing human error and safety hazards. The entire battery recycling system features fully enclosed design, coupled with advanced dust and exhaust gas treatment systems, ensuring pollution-free operation.

DOING lithium-ion battery recycling machine

DOING lithium-ion battery recycling machine

③ DOING lithium-ion battery recycling machine offers flexible production capacities ranging from 500 kg/hour to 2000 kg/hour and provides customized battery recycling solutions to meet the needs of businesses of all sizes. With decades of industry experience, we provide comprehensive support from consultation and factory design to equipment installation and after-sales maintenance.

Finally, policy guidance and industrial collaboration are indispensable. Clear mandatory recycling targets, sound standards across the entire value chain, and promoting the concept of "designing batteries for recycling" will fundamentally optimize the market environment and guide the entire industry chain to build a green and sustainable closed-loop ecosystem.

Improving the lithium battery recycling percentage is a continuous process that requires the joint efforts of technology, policy, and public awareness. DOING is committed to working with industry partners to contribute to improving the lithium-ion battery recycling rate by providing practical lithium-ion battery recycling machine, lowering the technical threshold and operating costs of recycling, and enhancing the economic and environmental benefits of the entire chain.