WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

India's immense agricultural output, which generates hundreds of millions of tonnes of biomass waste annually, has created a highly profitable opportunity in the charcoal briquetting sector. With the country seeking sustainable alternatives to traditional wood charcoal and fossil fuels, converting widely available agro-waste into efficient solid biofuel presents a compelling business model. The profitability of charcoal briquette production in India hinges on three critical factors: access to low-cost agricultural residues, efficient processing technology adapted to local conditions, and growing market demand from both industrial and domestic consumers.

Indian biomass waste for making charcoal briquettes

Indian biomass waste for making charcoal briquettes

The Indian context offers distinct advantages for briquette producers. Raw materials—such as rice husk from Punjab and West Bengal, sugarcane bagasse from Maharashtra and Uttar Pradesh, coconut shells from coastal regions, and sawdust from timber hubs—are abundantly available and often acquired at minimal cost. This easy access to feedstock, combined with supportive government policies promoting bio-energy and waste-to-wealth initiatives, creates an ideal environment for profitable charcoal briquette production in India. The primary investment focus, therefore, shifts to selecting robust and efficient processing technology that can handle India's diverse biomass varieties and climatic conditions.

Production Cost: Biomass carbonization raw materials like rice husk, bagasse, and groundnut shells can often be sourced for as little as ₹1,500-2,500 per tonne. When combined with other operational costs—including power, labour, and packaging—the total production cost typically ranges between ₹15,000-18,000 per tonne. These figures are highly favourable due to India's low-cost biomass supply and labour markets, enhancing the overall profitability of charcoal briquette production in India.

The market value of the final briquettes

The market value of the final briquettes

Market Selling Price: The market value of the final briquettes depends on the raw material used and the product quality. Briquettes made from common agro-waste sell for approximately ₹28,000-32,000 per tonne. However, premium briquettes produced from high-density woods like mango, acacia, or sheesham can command significantly higher prices, ranging from ₹40,000-55,000 per tonne, especially in urban markets and for industrial applications.

Profit Analysis: After deducting production costs, producers can realise a clear profit of at least ₹12,000-15,000 per tonne. This strong return potential makes charcoal briquette production in India a highly attractive business venture within the Indian market.

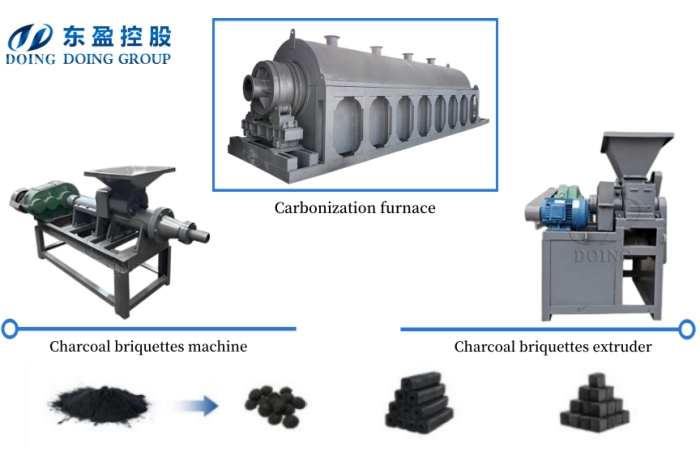

Successful charcoal briquette production in India requires careful attention to local conditions. Sourcing consistent, quality raw materials is paramount; partnering directly with local rice mills, sugar factories, or timber units can ensure a stable supply chain. The core production process includes multiple stages: crushing large biomass feedstocks using a crusher, drying (which is crucial in India's humid regions), carbonizing using a carbonization furnace, and finally pressing them into charcoal briquettes using a carbon press.

DOING complete charcoal briquette production line

DOING complete charcoal briquette production line

For Indian entrepreneurs, investing in a complete production line with a quality charcoal briquettes machine from an established supplier like DOING is crucial. Our machinery is engineered to handle the specific challenges of Indian biomass and is designed for energy efficiency, a key concern given local power costs and variability. Each step—from raw material preparation to final carbonization—must be meticulously controlled to ensure the output meets the quality standards demanded by commercial buyers.

Charcoal briquette production in India demonstrates remarkable profitability by efficiently valorising the country's abundant agricultural waste. With low material costs, high-value output, and a favourable market landscape, this business model offers substantial economic returns with minimal investment risk. As India continues to seek sustainable energy solutions, briquette producers who invest in proper technology now will be well-positioned to capitalise on this growing demand.

DOING charcoal briquette production machine service team

DOING charcoal briquette production machine service team

As a professional carbonization equipment manufacturer with over 15 years of global experience, including installations across India, DOING Company offers complete charcoal briquetting solutions tailored to the Indian context. We provide comprehensive technical support, on-site installation guidance, and reliable after-sales service to ensure your venture achieves optimal productivity and profitability of charcoal briquette production in India. If you are exploring the potential of charcoal briquette production in India, please feel free to contact us for a detailed consultation about our charcoal briquettes machine and complete production solutions.