WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Photovoltaic glass accounts for a significant portion of the weight of scrap solar panel modules (typically 70%-80%) and has high recycling value, the technological level of glass removal machine directly determines the efficiency and ultimate profitability of the recycling line. So, what recycling processes do professional solar panel glass removal machines use to achieve this critical step? Here Henan Doing Company listed three key ways to remove the glass from solar panel scrap:

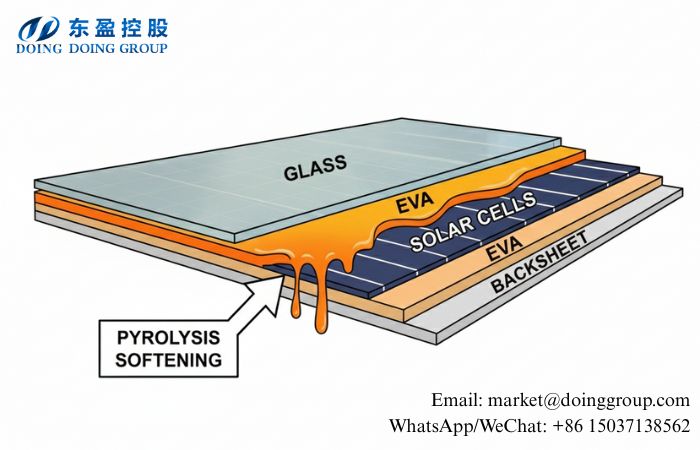

The primary task of solar panel glass removal machine is to process the adhesive—EVA film—between the glass and the solar cells. At room temperature, the EVA layer adheres very strongly to the glass, and direct physical removal can easily lead to glass breakage, mixing of impurities, and a reduction in recycling value.

Solar panel heating and softening process for glass recycling

Solar panel heating and softening process for glass recycling

Therefore, mature glass removal machines typically employ the pyrolysis softening process. Using heating technologies such as electric heating wires, the temperature is precisely controlled to soften the EVA adhesive layer in the solar panels. This process effectively reduces the adhesion between the glass and the solar cells, laying the foundation for subsequent separation. The heating system design ensures uniform temperature distribution, avoiding localized overheating or insufficient heating, thus guaranteeing the perfect separation of the glass and the solar panel.

The softened solar panels enter the second section – the conveying process. This part utilizes an automated conveyor belt system to smoothly and efficiently transport the heated photovoltaic panels to the crushing area. The conveyor belt design takes into account the size and weight of the solar panels, ensuring stability and safety during transportation. In addition, the conveying system is equipped with automatic detection devices that monitor the position and status of the solar panels in real time, providing accurate information support for subsequent crushing operations.

The third part of the solar panel glass removal machine is the crushing and removal process, which is a crucial step in separating the glass from the rest of the solar panel. After being conveyed to the crusher, the solar panels are thoroughly crushed by high-speed rotating blades and a robust crushing chamber, completely removing the glass from the PV panels.

The solar panel glass removal machine, through precise heating and crushing process, enables high-purity glass recovery, which can be directly used in the secondary recycling process to produce new solar panels, maximizing resource utilization.

Solar panel glass removal machine

Solar panel glass removal machine

As a manufacturer specializing in the photovoltaic environmental protection field, Henan Doing Company understands that every detail of the recycling process, whether it's the removal of aluminum frames or glass from solar panels, or the dismantling and recycling of solar panel cells, is crucial to our customers' return on investment. Our solar panel glass removal machine, combining an efficient pyrolysis system with a precise mechanical separation structure, has been successfully used in multiple recycling projects in the UK, India, and other countries, demonstrating excellent stability:

High-purity recycling: The resulting glass fragments have a purity of up to 98%, providing high-quality raw materials for secondary recycling production.

High-purity solar panel glass disassembly and recycling

High-purity solar panel glass disassembly and recycling

Highly automated: Utilizing PLC automatic control system, the entire recycling process is automated. Operators only need to set parameters through the control panel to complete a series of processes including heating, conveying, and crushing.

Environmentally friendly and pollution-free: The entire solar panel recycling process is conducted in a closed environment, and is equipped with dust removal and environmental protection devices to effectively control dust and harmful gas emissions.

We are committed to providing our customers with environmentally compliant and economically viable photovoltaic panel recycling machine solutions. If you are interested in the specific technical parameters, processing capacity, or pricing of our solar panel glass removal machine, or would like to learn more about the entire solar panel recycling production line, please feel free to contact us.