WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

India's rapidly growing electronics consumption has created a thriving opportunity in PCB recycling. With the country generating approximately 3.2 million metric tons of e-waste annually - ranking fifth globally - discarded printed circuit boards represent a particularly valuable segment of this waste stream. Each PCB contains significant amounts of recoverable metals, typically including 20-30% copper along with valuable traces of gold, silver, and palladium. When properly processed, these materials can yield substantial returns in India's burgeoning metal markets.

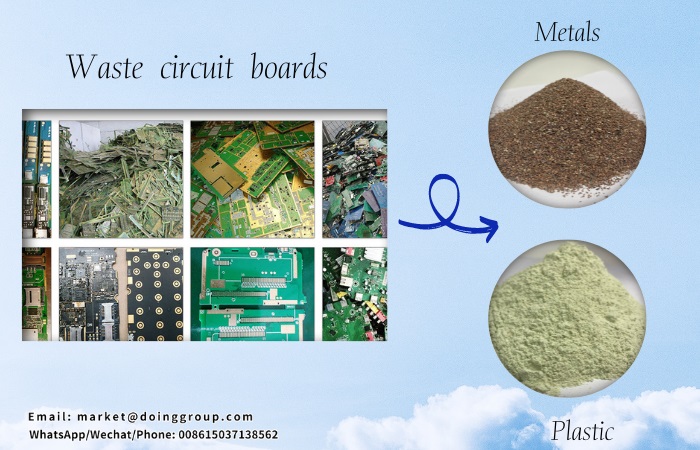

Products separated from waste circuit boards

Products separated from waste circuit boards

Several factors make India an especially favorable environment for PCB recycling businesses. The government's implementation of the E-Waste Management Rules 2022 has created a regulatory framework that incentivizes formal recycling operations. Additionally, India's vast informal waste collection network provides ready access to raw materials, often at very low acquisition costs. The combination of easily available feedstock and strong demand for recovered metals creates ideal conditions for profitable operations.

Waste PCB board recycling situation and policy trends

Waste PCB board recycling situation and policy trends

To capitalize on this opportunity, recyclers need efficient processing solutions that maximize metal recovery while meeting India's environmental standards. This is where advanced recycling technology becomes crucial. Modern equipment can separate and recover up to 99% of the valuable metals contained in waste PCBs, transforming what was once considered trash into a significant revenue stream. DOING's specialized PCB recycling systems are particularly well-suited to the Indian market. The equipment utilizes a sophisticated dry separation process that begins with shredding and crushing, followed by multiple stages of separation including magnetic, gravity, and electrostatic methods. This comprehensive approach ensures maximum metal recovery while maintaining low operational costs - a critical factor for profitability in India's competitive recycling sector.

DOING waste PCB board recycling equipment

DOING waste PCB board recycling equipment

The environmental benefits of proper PCB recycling align perfectly with India's sustainability goals. DOING's systems include integrated dust collection and air purification features that help operators comply with local regulations while protecting worker health. These systems also eliminate the need for chemical processing, making them both environmentally friendly and economically efficient.

To help you better understand the profit margins of recycling PCBs in India, we have combined Indian customers and market feedback to create a profit analysis table for your reference:

| Daily Operating Costs | |||||

| No. | Item | Quantity | Unit Price | Cost | Total Cost |

| 1 | Waste Circuit Board | 100kg/h*10h=1T | $800/ton | $800 | $1,100 |

| 2 | Electricity | 40kw/h*10h=400kwh | $0.10/kWh | $40 | |

| 3 | Labor | 2 workers | $12/day per worker | $24 | |

| Daily Revenue | |||||

| No. | Product | Quantity | Unit Price | Revenue | Total Revenue |

| 1 | Metal | 1T*18%=0.18T | $7,500/ton | $1,350 | $1,570 |

| 2 | Resin Powder | 1T*82%=0.82T | $120/ton | $98 | |

| Daily Profit = Revenue - Cost = $1,570 - $1,100 = $470 | |||||

| Note: The above data comes from the Internet and may fluctuate. | |||||

For Indian entrepreneurs evaluating the profitability of PCB recycling, the economics are compelling. With DOING's high-recovery PCB board recycling equipment, operators can process waste PCBs into high-purity metal products that command premium prices. The combination of low material acquisition costs, high-value outputs, and efficient processing creates strong profit margins that make this business opportunity particularly attractive in the Indian context.

As India's electronics market continues to expand, the supply of waste PCBs will only increase. Forward-thinking recyclers who invest in proper processing technology now will be well-positioned to benefit from this growing waste stream. DOING's solutions offer Indian businesses the perfect tool to transform e-waste into profits while contributing to the country's circular economy goals.