WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

As the first generation of solar panels reaches the end of its lifespan, the industry faces a dual challenge: preventing environmental harm from panel waste and recovering the valuable materials they contain. For recyclers, solar farm operators, and waste management companies, this isn't just an environmental issue—it's a financial decision. At the heart of this decision is recycling equipment, where the choice of technology directly determines both operational costs and potential revenue. Henan Doing Holdings Co., Ltd. addresses this challenge with solar panel recycling equipment designed to transform end-of-life panels into an economic opportunity.

Recyclable end-of-life solar panels

Recyclable end-of-life solar panels

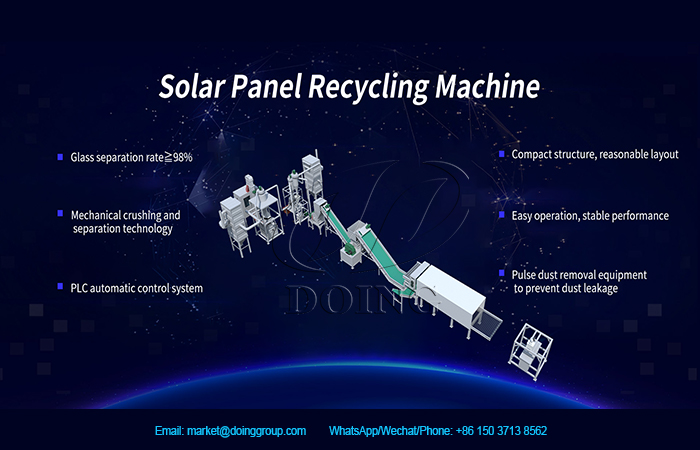

DOING's solar panel recycling equipment stands out through its automated, PLC-controlled processing system that delivers measurable advantages in both efficiency and environmental performance.

The recycling process begins with automated frame removal and proceeds through controlled crushing, fine grinding, and advanced separation stages. What sets the system apart is its use of dry physical separation technology—specifically combining electrostatic and gravity-based methods—which achieves material purity rates exceeding 99%. This technical approach eliminates water pollution concerns while recovering over 98% of valuable materials including silicon, silver, copper, and high-purity glass.

For operators concerned about environmental compliance, the system incorporates an intelligent pulse dust collection system that effectively controls emissions. This engineering focus ensures operations can meet stringent environmental standards while maintaining community relations—a significant consideration for recycling facilities in populated areas.

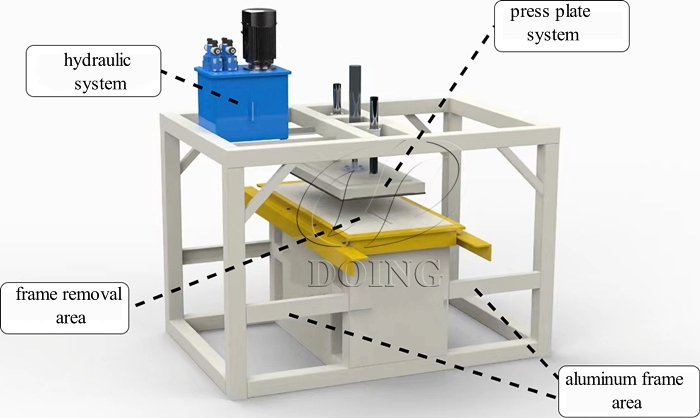

Solar panel aluminum frame dismantling machine

Solar panel aluminum frame dismantling machine

2.1 Cost Control Through Automated Efficiency

The economic case for DOING's photovoltaic PV panels recycling equipment begins with its significant cost-saving features. The fully automated system requires only 1-2 operators per shift, substantially reducing labor costs—typically one of the largest expenses in recycling operations. With throughput capacities ranging from 500 kg/h to 1,000 kg/h, the equipment achieves economies of scale that lower processing costs per scrap PV panel.

Beyond labor savings, the system's energy-efficient design minimizes power consumption, while the dry processing method eliminates water treatment costs. Perhaps most importantly, proper recycling with this equipment prevents potential environmental penalties and disposal fees associated with improper panel disposal—a growing concern as regulations tighten globally.

2.2 Revenue Optimization Through Premium Material Recovery

On the revenue side, DOING's solar panels recycling equipment creates multiple income streams. The high-purity recovered materials command premium prices in recycling markets, with silicon, silver, and copper having particularly strong demand. The 98%+ recovery rate ensures maximum value extraction from every panel processed.

Businesses using this solar panel treatment recycling machine also gain intangible benefits that impact the bottom line. Demonstrating environmentally responsible recycling practices enhances sustainability credentials, appealing to environmentally conscious partners and customers. This can lead to preferred supplier status with manufacturers implementing take-back programs and create opportunities for recycling service contracts with solar farm operators—particularly relevant as extended producer responsibility regulations emerge in more markets.

DOING's solar panel recycling equipment

DOING's solar panel recycling equipment

For companies evaluating recycling options, DOING's solar panel recycling equipment addresses several practical concerns. Understanding that solar recycling operations vary significantly in volume and scope, DOING offers customized solutions to match specific operational requirements. Our standard configurations include systems with processing capacities of 500kg/h and 1000kg/h, suitable for most medium to large-scale recycling operations. For clients with smaller processing needs or those requiring even higher throughput capabilities, we provide tailored configurations that maintain the same high recovery standards and operational efficiency. This flexible approach ensures that whether you're establishing a new recycling facility or expanding an existing operation, you receive equipment precisely matched to your current volume requirements while maintaining the capability to scale as your business grows—essential for businesses seeking growth in the evolving scrap solar panel recycling market. This scalability reduces initial investment risk while providing a path to expand alongside the growing stream of end-of-life panels, which is projected to increase significantly over the coming decade.

Advantages of DOING solar panel recycling equipment

Advantages of DOING solar panel recycling equipment

DOING's solar panel recycling equipment represents more than just processing technology—it's a business solution that balances environmental responsibility with economic practicality. By achieving high material recovery rates through automated, efficient processes, this technology helps businesses manage end-of-life panels effectively while creating tangible value from reclaimed materials. In an industry where equipment choice directly impacts profitability, DOING's systems offer a pathway to turn the challenge of solar panel waste into a sustainable business opportunity.