WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

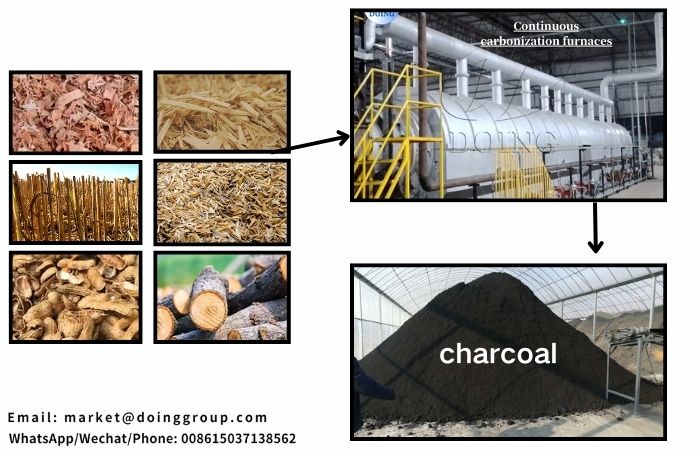

In the context of modern environmental protection and sustainable development, utilizing agricultural waste to produce charcoal has become an important way to achieve both environmental and economic benefits. Rice husks, a common agricultural byproduct, are rich in organic matter and can be converted into high-quality charcoal after carbonization. So, how much charcoal can one ton of rice husks produce?

Under ideal conditions, 1 ton of rice husks can produce approximately 300 kilograms of charcoal during the carbonization process. Actual carbonization yield is affected by various factors, including the characteristics of the rice husk raw material itself, the performance of the carbonization equipment, and the operating process. Overall, using conventional carbonization processes, one ton of rice husks typically produces 260-280 kilograms of finished rice husk charcoal, meaning approximately 3 tons of rice husks can produce 1 ton of finished charcoal.

Charcoal produced from rice husks

Charcoal produced from rice husks

The key to increasing charcoal production lies in optimizing the carbonization process, from raw material pretreatment and carbonization process control to the selection of carbonization machine. Here are some effective methods to improve charcoal yield:

The moisture content of rice husks has a significant impact on charcoal yield. Raw materials with higher moisture content require more heat to evaporate moisture during carbonization, which not only increases fuel costs but also prolongs carbonization time, leading to excessive consumption of some charcoal in the furnace and reducing the charcoal yield. It is recommended to pre-dry the rice husks, and if necessary, use a dryer to keep the moisture content at a low level (below 15%), which helps improve charcoal production efficiency.

Biomass carbonization drying oven

Biomass carbonization drying oven

Carbonization temperature and time are two important factors determining charcoal yield and quality. Too low a temperature or insufficient carbonization time may result in incomplete reaction of the rice husk raw material, leading to poor charcoal quality; too high a temperature or too long a time may cause excessive consumption of some carbon elements, resulting in very low yield. By properly adjusting the carbonization temperature curve and residence time, charcoal production can be increased while ensuring charcoal quality.

It is recommended to use a modern charcoal kiln with precise temperature and time control, such as the DOING biomass carbonization machine. This charcoal production line is equipped with a PLC intelligent control system, which can achieve precise temperature control compared to traditional burners. It can stably control the carbonization temperature at around 400℃ and keep the carbonization time at 20-30 minutes. This ensures that the volatile substances in the rice husks are fully decomposed while avoiding excessive loss of finished charcoal in the carbonization furnace, thereby increasing charcoal production while ensuring charcoal quality.

PLC intelligent control system for charcoal production

PLC intelligent control system for charcoal production

The performance of the carbonization equipment directly affects the charcoal yield from rice husks. For example, the equipment's sealing performance, heating uniformity, and insulation effect are crucial.

DOING's continuous biomass carbonization machine employs a multi-layer insulation design and a uniform heating system, effectively reducing heat loss and promoting thorough carbonization of the raw materials, thereby helping users increase overall charcoal production. Its advantages lie in its excellent sealing performance, effectively isolating oxygen and preventing the rice husk charcoal from oxidizing and burning (turning to ash) at high temperatures. Simultaneously, it allows for the recycling of exhaust gas as energy, saving energy, reducing consumption, and minimizing carbon element loss.

DOING continuous biomass carbonization machine

DOING continuous biomass carbonization machine

In addition, the continuous rice husk carbonization machine is equipped with a high-efficiency charcoal discharge system, enabling rapid cooling of the rice husk charcoal and preventing spontaneous combustion of the finished charcoal upon contact with air. This ensures safe production and helps retain more charcoal.

To maintain the efficient operation of the charcoal manufacturing process, regular maintenance and inspection of the carbonization equipment are crucial. It is recommended to regularly clean the inside of the carbonization furnace, check the sealing structure, and operate according to specifications. This helps maintain the equipment in good condition and reduces fluctuations in charcoal production caused by malfunctions or improper operation.

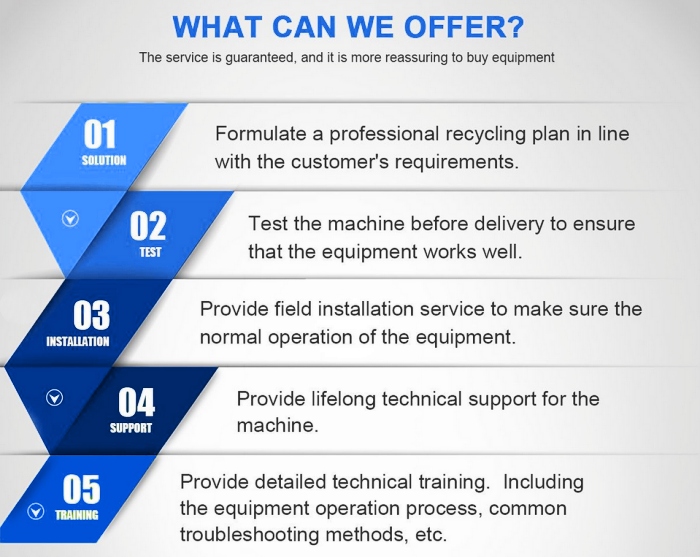

DOING provides comprehensive equipment services, including equipment consultation and selection, installation and commissioning, operation training, and after-sales maintenance, helping customers maintain stable operation of carbonization machine and supporting stable charcoal production.

Equipment services provided by DOING

Equipment services provided by DOING

In summary, to improve the charcoal yield of rice husk charcoal, you can start from the above key aspects, minimize unnecessary losses, increase the charcoal yield of rice husk carbonization, and thus improve the overall profitability of the charcoal production project. If you have any further questions about increasing rice husk carbonization yield or selecting carbonization machine, please feel free to contact us. Our team is happy to answer your questions and assist you in developing a suitable charcoal manufacturing solution.