WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

What is a Continuous Feed Biochar Reactor?

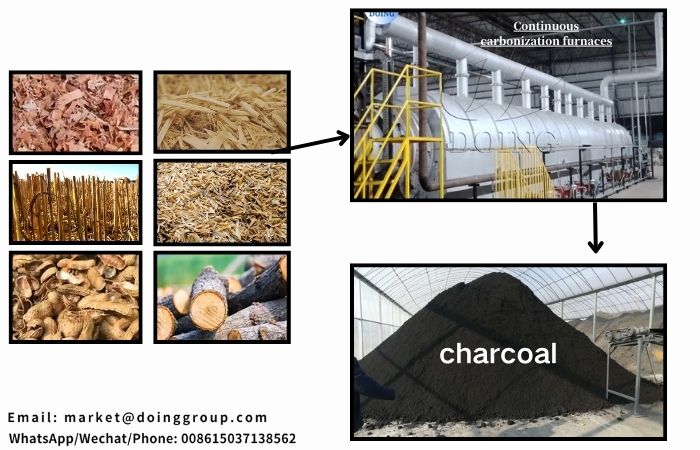

A Continuous Feed Biochar Reactor is a system that allows for the ongoing conversion of biomass into biochar through a continuous input of feedstock. The reactor works by heating organic materials in a low-oxygen environment, producing biochar as a valuable byproduct.

Unlike traditional batch carbonization methods, which are time-consuming and inefficient, continuous feed biochar reactors can improve efficiency and yield. That’s why more and more companies are investing in continuous biochar production.

Continuous Feed Biochar Reactor

Continuous Feed Biochar Reactor

The Continuous Feed Biochar Reactor uses an automatic feeding system to achieve uniform and stable feeding of raw materials through a precisely controlled screw conveyor or belt conveyor. The PLC control system can monitor the feed speed and material flow in real time to ensure that the raw materials enter the reactor at the optimal rate.

Automatic feeding system 3D diagram

Automatic feeding system 3D diagram

Besides, the feed port is designed with high-temperature resistant alloy materials and can handle a variety of biomass raw materials with a particle size range of 5-30mm. This intelligent continuous feeding mechanism not only ensures efficient production, but also significantly reduces downtime, maximizing output and operational stability.

This type of biomass carbonization reactor is ideal for large-scale operations that require a steady flow of biochar production. Its design ensures that the biomass is processed efficiently, making it a cost-effective solution for industries such as agriculture, waste management, and environmental remediation.

DOING Continuous Feed Biochar Reactor for Sale

DOING Continuous Feed Biochar Reactor for Sale

At Henan DOING company, we specialize in designing and manufacturing high-quality continuous feed biochar reactors tailored to meet your production needs. Our advanced carbonization technology ensures efficient, environmentallyfriendly, and cost-effective biochar production.

Key Features of DOING Continuous Feed Biochar Reactor:

1.Higher Efficiency

Continuous feeding means there is no downtime between batches. DOING Continuous Feed Biochar Reactor can be operated 24/7 and significantly increases biochar production. Our standard biochar carbonization reactor can process 2-3 tons of raw materials per hour, and the daily processing capacity can reach 48-72 tons. Our reactor is very suitable for large-scale production. For large-scale production needs, we also provide customized solutions to maximize production efficiency while reducing labor costs.

2.Versatile Raw Material Compatibility

DOING Continuous Feed Biochar Reactor is suitable for a variety of biomass materials, including various agricultural wastes, such as palm shells, wood, coconut shells, corn cobs, rice husks, straw, sawdust, bamboo, etc. The raw material flexibility enables you to adapt to local resource supply and reduce production costs.

Biomass materials for Continuous Feed Biochar Reactor: agricultural wastes

Biomass materials for Continuous Feed Biochar Reactor: agricultural wastes

3.Energy-Saving & Eco-Friendly

Our Continuous Feed Biochar Reactors feature an advanced heat recovery system that reduces energy consumption and minimizes emissions. The automated carbonization process ensures uniform heating, resulting in high-quality biochar with consistent properties. Besides, Our Continuous Feed Biochar Reactor is equipped with a dust removal system and a cooling system to avoid air pollution problems.

Moreover, DOING company can provide customized equipment solutions and reactors of different sizes and designs to match your production scale and biomass feeding carbonization raw material type. We also provide professional technical support and after-sales service to ensure the smooth operation of the equipment in the future.