WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

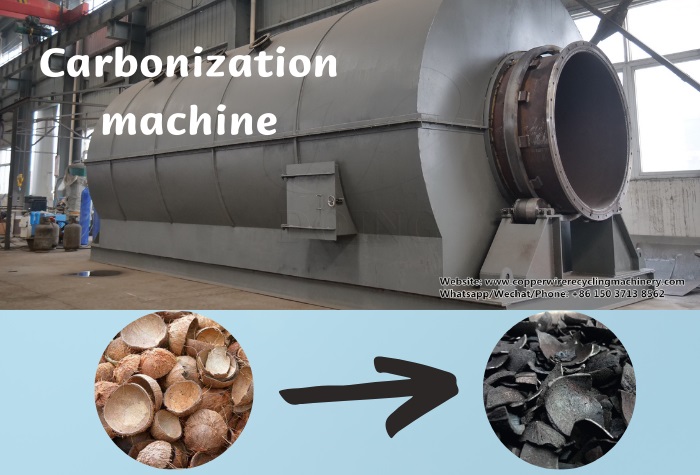

In today's era of green environmental protection and energy conservation and emission reduction, we are committed to the reuse of recyclable resources, striving to promote the development of renewable energy while reducing environmental pressure. Biomass carbonization, especially the carbonization of agricultural and forestry waste represented by straw, is an industry formed under this concept.

Continuous carbonization furnace

Continuous carbonization furnace

Agricultural and forestry waste, such as straw, coconut shells, apricot shells, peach shells, sawdust, etc., are carbonized into activated carbon and are widely used in air purification, water purification and other scenes in life. Traditionally, the production of activated carbon relies on coal, but nowadays, replacing coal with biomass raw materials not only reduces dependence on fossil fuels, but also shows irreplaceable advantages due to its unique adsorption properties.

The continuous carbonization furnace, as an innovative equipment that efficiently solves the problem of carbonization of agricultural and forestry waste, is in sharp contrast to traditional earth kilns, vertical kilns and static/horizontal carbonization furnaces.

Continuous carbonization furnace

Continuous carbonization furnace

In the traditional carbonization method, the material needs to be loaded at one time, the bottom is heated, and the carbonization is carried out by dry distillation under anoxic conditions. The production efficiency is low, and a cycle often exceeds 8 hours. In addition, the material needs to wait for the equipment to cool before entering and exiting, which is time-consuming and increases energy consumption.

The continuous carbonization furnace adopts a double-cylinder design, with the inner cylinder drying and the outer cylinder carbonizing. The material is spirally advanced in the rotary furnace body to achieve continuous addition and carbonization of the material. The material flows from the inner cylinder to the outer cylinder, and then the outer cylinder spiral guides the reflux until the carbonization process is completed, and the material is discharged after cooling. This design ensures the continuous processing of materials and significantly improves production efficiency.

Continuous carbonization furnace

Continuous carbonization furnace

The high efficiency and uniformity of the drum-type continuous carbonization furnace are reflected in its uniform heating and rapid heat transfer. The average hourly carbonization capacity reaches 1-3 tons, which is 10-20 times more efficient than that of a static carbonization furnace.

When processing sawdust, traditional earth kilns or static carbonization furnaces face problems such as poor environmental protection, smoke pollution, imperfect recovery of carbonization byproducts, and increased costs. In addition, due to the small particle size and compacted stacking of sawdust, it is difficult to transfer heat, and even if it is processed for a long time, it is difficult to achieve complete carbonization.

Continuous carbonization furnace

Continuous carbonization furnace

Henan DOING continuous carbonization furnace, with the help of new technological innovations, comprehensively optimizes the above problems. Continuous rotary carbonization ensures that the material is fully in contact with the furnace wall, is evenly heated, and achieves complete carbonization. It not only improves production efficiency, but also sets a new industry benchmark in environmental protection and resource conservation. For more relevant information, please pay attention to other articles on the website and contact us.