WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

With the rapid development of new energy technology, lithium batteries are increasingly used as an important component of electric vehicles, portable electronic devices and energy storage systems. However, with the extension of the use cycle and the replacement of equipment, scrap lithium batteries have gradually become a hot topic of social concern. So, what is the value of scrap lithium batteries? We can explore it from multiple angles.

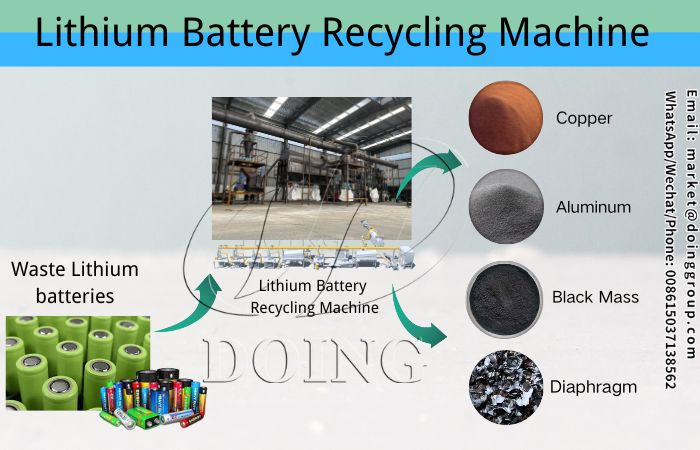

Waste lithium batteries contain a variety of valuable metal materials, including lithium, cobalt, nickel, aluminum, etc. These metal materials have a wide range of application needs in the fields of electronic product manufacturing, new energy industry, etc. Through professional lithium battery recycling plant, these valuable components can be effectively separated and extracted to achieve secondary utilization of resources.

Valuable metals extracted from scrap lithium batteries

Valuable metals extracted from scrap lithium batteries

In addition, materials such as electrolytes and diaphragms in scrap lithium batteries also have recycling value. Reasonable treatment of these materials can not only reduce environmental pollution, but also reduce energy consumption in the production of new materials.

Through disassembly, crushing, sorting and other processes, the core components can be extracted from waste lithium batteries, including positive electrode materials (lithium, cobalt, nickel, etc.), negative electrode materials (graphite), copper and aluminum, etc. Among them, positive electrode materials account for about 30%-50%, especially cobalt and nickel, which have high contents (cobalt accounts for about 5%-20%, and nickel accounts for about 5%-15%), while lithium accounts for about 1%-3%.

According to market conditions, the price of cobalt is about US$50-60 per kilogram, nickel is about US$15-20 per kilogram, and lithium is usually US$20-30 per kilogram. At the same time, copper and aluminum foils and graphite also have high recycling value. Therefore, through efficient recycling processes, the resource utilization of scrap lithium batteries can create significant economic benefits, and the economic value of recycling is considerable.

The recycling of scrap lithium batteries is not only economically valuable. If waste lithium batteries are discarded or improperly handled, the heavy metals and harmful substances in them may penetrate into the soil and water sources, causing long-term harm to the ecological environment. The use of scientific lithium battery recycling technology to effectively isolate harmful substances in scrap lithium batteries can not only effectively avoid environmental pollution, but also maximize the utilization of resources.

Lithium battery recycling plant for recycling scrap lithium batteries

Lithium battery recycling plant for recycling scrap lithium batteries

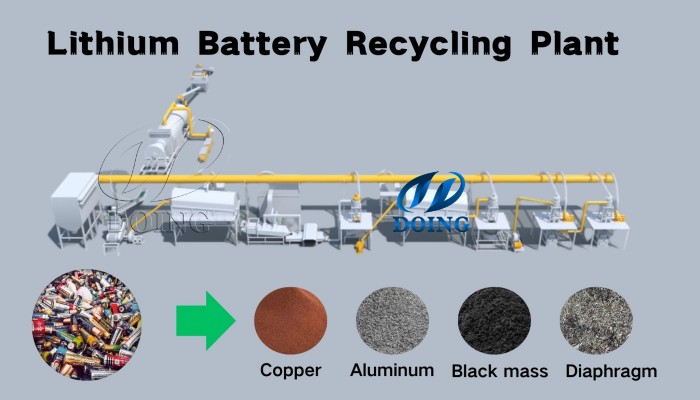

The key to efficiently recovering the value of scrap lithium batteries is to choose the right lithium battery recycling machine. After years of technical accumulation and market verification, DOING lithium battery recycling plant has been stable and reliable in terms of processing efficiency, resource recovery rate and environmental protection indicators.

1. DOING battery recycling machine adopts multi-stage crushing and sorting processes. Through efficient sorting technology, it can achieve a recovery rate of more than 98%. Help customers to establish an efficient recycling production line with reasonable investment and quickly realize a return on investment.

2. During the entire process of recycling scrap lithium batteries, DOING lithium battery recycling plant effectively controls dust and harmful gases through a fully enclosed treatment process. At the same time, it is equipped with an exhaust gas treatment system, and the emissions meet international environmental standards.

3. Our lithium battery recycling production line consists of: shredder, crusher, screening equipment, pulverizer and airflow sorting machine, which can be flexibly configured according to different processing requirements. Therefore, we provide equipment with different processing capacities, such as 500kg/h, 1000kg/h and 2000kg/h, which is also convenient for later capacity expansion and technology upgrades.

Scrap lithium battery recycling plant production line

Scrap lithium battery recycling plant production line

4. By adopting a PLC automatic control system, it is easy to operate and can reduce manual operation links. At the same time, our lithium battery recycling process can monitor key parameters in real time to ensure that the entire process runs stably and efficiently.

5. Our professional team provides a full range of pre-sales and after-sales services, including full technical support such as equipment installation and commissioning, operation training, and regular maintenance services to ensure long-term stable operation of the equipment and help companies improve production efficiency.

If you have more questions about the recycling value of scrap lithium batteries, or need to know more about our lithium battery recycling plant, please feel free to contact us. Our professional team will provide you with detailed technical advice and solution suggestions.