WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Radiators, which are usually contained in cars and air conditioner, are mainly made of copper and aluminum. Copper and aluminum can be recycled to bring high value. Well, here question is coming: how to separate copper and aluminum from the waste radiators?

Copper and aluminum in waste radiator

Copper and aluminum in waste radiator

Henan Doing Environmental Protection Technology Co., Ltd designed two types radiator recycling machine, in order to separate copper and aluminum from waste radiators. One is small-scale radiator recycling machine, the other is large-scale radiator recycling machine.

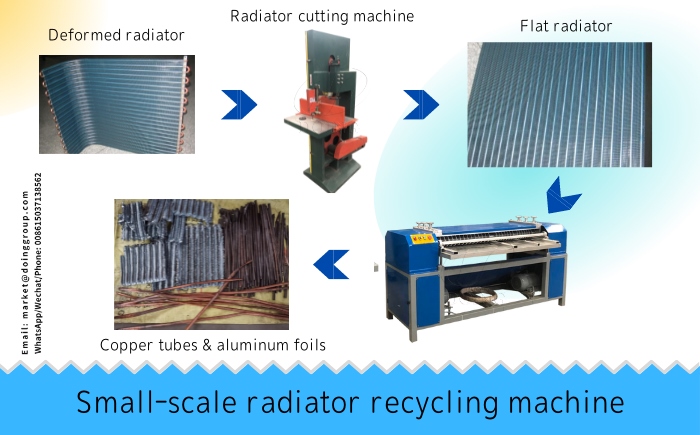

Small-scale radiator recycling machine

Small-scale radiator recycling machine

Small-scale radiator recycling machine, or you can call it stripping type radiator recycling machine and radiator stripping machine, is used to process undeformed and flat air conditioner radiators. Firstly, you should use a radiator cutting machine to cut the radiators into suitable size (19mm, 21mm and 25mm), then the copper tubes will be easily separated from aluminum foils by small-scale radiator recycling machine.

Advantages:

1. Small footprint - simple integrated design, small land occupied;

2. Low cost - less power consumption, labor force saving;

3. Simple operate - one labor force can operate.

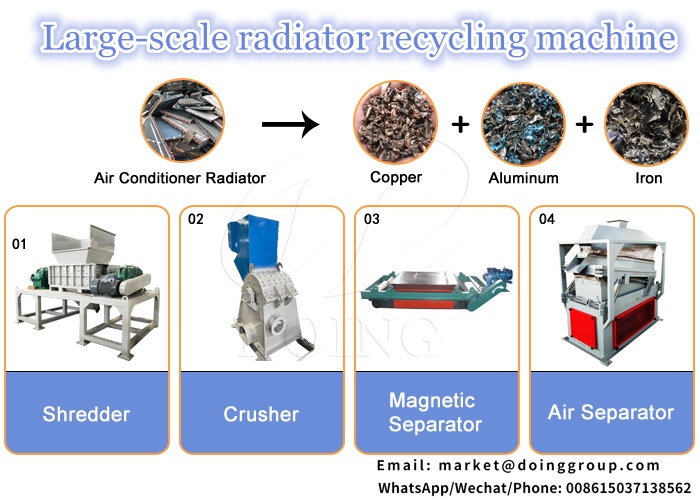

Large-scale radiator recycling machine

Large-scale radiator recycling machine

Large-scale radiator recycling machine, which is also called copper aluminum radiator recycling machine, can separate copper metal from aluminum metal in waste air conditioner radiators, car water tanks, refrigerator crushed materials, etc. The whole processing capacity includes shredding, crushing, negative-pressure baffling separation and air separation. Through the above procedure process, copper can be separated from aluminum with the separation rate of 99%.

Advantages:

1. Environmental protection - dry type physical separation method and closed dust removal system;

2. High degree of automation - PLC control system;

3. High working efficiency - 500-2000kg/h processing capacity.

If you have interest in one of the two, and want to know more information about the machine. Please contact us and we will give you our best support.