2015 china best circuit board recycling machine/waste PCB recycling equipment with factory price

Product

- Copper wire granulator machine

- Cable Wire Recycling Copper Separating Machine

- Cable recycling machine

- Professional Copper Cable Wire Recycling machine

- Copper cable separation

- Scrap copper wire recycling equipment

- High recycling rate of PCB Recycling Machine

- Waste Cable Recycling Copper Machine

- Scrap Copper granulator Cable wire Recycling Machine

- China manufacturers copper wire waste recycling machine

- Circuit board separator machine

- Recycling circuit board machine

- Waste circuit board recycling equipment

- 2015 china best circuit board recycling machine/waste PCB recycling equipment with factory price

- Manufacture PCB recycling plant

- PCB board separation machine

- Circuit board recycling equipment

- Eco-friendly E-waste recycling plant

- Advanced technology circuit board recycling machine

- 2015 hottest PCB recycling machine

- Aluminum plastic tube separation equipment

- Aluminum separating eauipment

- Aluminum cans recycling machine

- Aluminum separation machine

- Separation aluminum and plastic recycling machine

- Aluminum recycling machine

- Machine manufacturers waste aluminum plastic separator

- Aluminum recycling equipment

- Waste aluminum plastic separation

- supplier waste aluminum plastic separator

News

1.Brief inroduction of the circuit board recycling machine/waste PCB recycling equipment

circuit board recycling machine/waste PCB recycling equipment

Circuit board recycling machine/waste PCB recycling equipment is developed in combination with advanced domestic and foreign technology. The equipment adopts advanced recycling process by physical methods. Such crushers and high voltage electrostatic separation devices developed by our company are of strong innovation, and their process lines for resource recycling are advanced and reasonable.

2.Advantages of circuit board recycling machine/waste PCB recycling equipment

♥. The grinder mill is very wear-resisting.

♥. The high voltage electrostatic system is centralized control, the equipment is very flexible.

♥. The separator rate and the purity is very high,the separator rate can reached 99.99%.

♥. Small power and less power consumption.

♥. A high degree of automation, covers less area.

♥. This set of PCB recycling equipment belong to dry recycling,smll noisy and no pollution.

♥. Perfect after sale service system,the 12 months warranty,free replacement parts,lifelong supply the parts in duty.

3.Working Principle of the circuit board recycling machine/waste PCB recycling equipment

circuit board recycling machine/waste PCB recycling equipment

Circuit board recycling machine/waste PCB recycling equipment(high voltage electrostatic separation type) adopts a process route that makes raw materials such as printed circuit boards to be a mixture of metal and resin fiber powder by dry crushing and pulverization and then separates the metals from the non-metal materials such as resin by high voltage electrostatic separator. To avoid dust pollution in the process, the equipment also uses the three-in-one dust removal equipment independently developed by the Doing company. This dust removal equipment has three-stage dust removal: cyclone dust removal, bag dust removal and dust removal by air cleaner. All of these effectively solve the problem of dust pollution with every index up to the national standard .

4.Application of the circuit board recycling machine/waste PCB recycling equipment

our circuit board recycling machine/waste PCB recycling equipment

♥. 1. waste circuit board

♥. 2. computer boards

♥. 3. TV boards

♥. 4. aluminum-plastic panels

♥. 5. copper-coated plates

♥. 6. printed circuit boards,ect

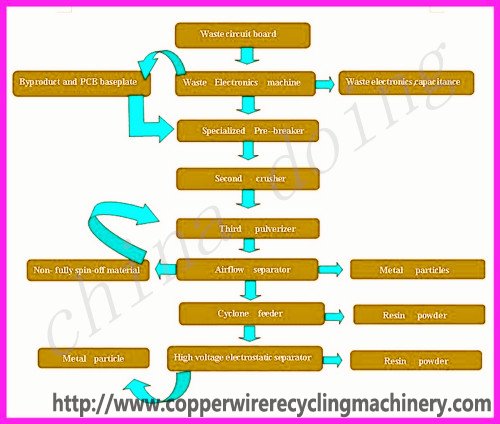

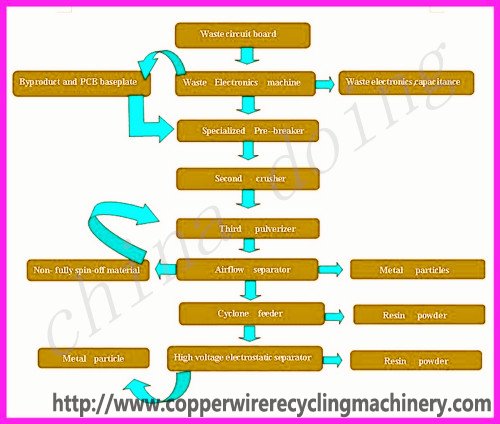

5.working flow of the circuit board recycling machine/waste PCB recycling equipment

6. Main data of the print circuit board recycling machine/waste PCB recycling equipment

5.working flow of the circuit board recycling machine/waste PCB recycling equipment

flow chart of printed cicuit board recycling machine/waste PCB recycling equipment

6. Main data of the print circuit board recycling machine/waste PCB recycling equipment

| Model | Voltage | Power | Capacity | Dimension | Weight |

| DYTM-400 | 380V | 22.45 kw | 150-200kg/H | 2700*1900*2300(mm) | 1200kg |

| DYTM-600 | 380V | 36 kw | 300-400kg/H | 3500*1900*2700(mm) | 3000kg |

| DYTM-800 | 380V | 75 kw | 500-600kg/H | 5500*4500*3300(mm) | 8000k |

7.Our Sweet Service of the printed circuit board recycling machine/waste PCB recycling equipment

♥. Pre-sale service:design and manufacture machines for you as your special requirements, provide you with project, process design, and purchase programm.

♥. On-sale service: accompany with you to look around our factory, explain the manufacture process of our printed circuit board recycling machine/waste PCB recycling equipment, and check the working performance of our machines.

♥. After-sale service: engineers are available to install and debugging equipments of the whole production line, besides, commissioning and training operators on site.