Circuit board separator machine

Product

- Copper wire granulator machine

- Cable Wire Recycling Copper Separating Machine

- Cable recycling machine

- Professional Copper Cable Wire Recycling machine

- Copper cable separation

- Scrap copper wire recycling equipment

- High recycling rate of PCB Recycling Machine

- Waste Cable Recycling Copper Machine

- Scrap Copper granulator Cable wire Recycling Machine

- China manufacturers copper wire waste recycling machine

- Circuit board separation machine

- Circuit board separator machine

- Recycling circuit board machine

- Waste circuit board recycling equipment

- 2015 china best circuit board recycling machine/waste PCB recycling equipment with factory price

- Manufacture PCB recycling plant

- PCB board separation machine

- Circuit board recycling equipment

- Eco-friendly E-waste recycling plant

- Advanced technology circuit board recycling machine

- Aluminum plastic tube separation equipment

- Aluminum separating eauipment

- Aluminum cans recycling machine

- Aluminum separation machine

- Separation aluminum and plastic recycling machine

- Aluminum recycling machine

- Machine manufacturers waste aluminum plastic separator

- Aluminum recycling equipment

- Waste aluminum plastic separation

- supplier waste aluminum plastic separator

News

FAQ

-

How about the market prospective of recycling waste copper wire?

-

Which type of wires and cables can be processed by cable recycling machine?

-

What requirements does waste aluminum plastic recycling equipment have for the raw material?

-

What about After-sales service of the circuit board recycling machine?

1.Basic introduction Circuit board separator machine

Circuit board separator machine

Circuit board separator machine(PCB separation recycling) is widely used for all kinds of circuit boards, PCB,FPC flexible circuit boards and so on. This technology can separate the materials containing the circuit board directly without disassembling.The circuit boards are separated and recycled by the following process: coarse material, magnetic separation in first step,fine breaking, dust collecting, winnowing, vibration screening, specific gravity separator, electric separation in second step.recovery rate can reach more than 99%.During the operation ,it only need to 1-2 people with fully automatic operation from feeding to sorting .It is named environmental dry separation, adopting physical method which doesn’t produce any pollution and doesn’t need heating ,setting on fire, water and any other chemical materials,low cost, high efficiency,non-pollution technology

2.Advantage of Circuit board separator machine

Circuit board separator machine

1.To avoid dust pollution in the process, the equipment also uses the three-in-one dust removal equipment independently developed by the compan;

2.This dust removal equipment has three-stage dust removal: cyclone dust removal, bag dust removal and dust removal by air cleaner;

3.All of these effectively solve the problem of dust pollution with every index up to the national standard.

4.Saving motive power and human power

5.Without Wastes.

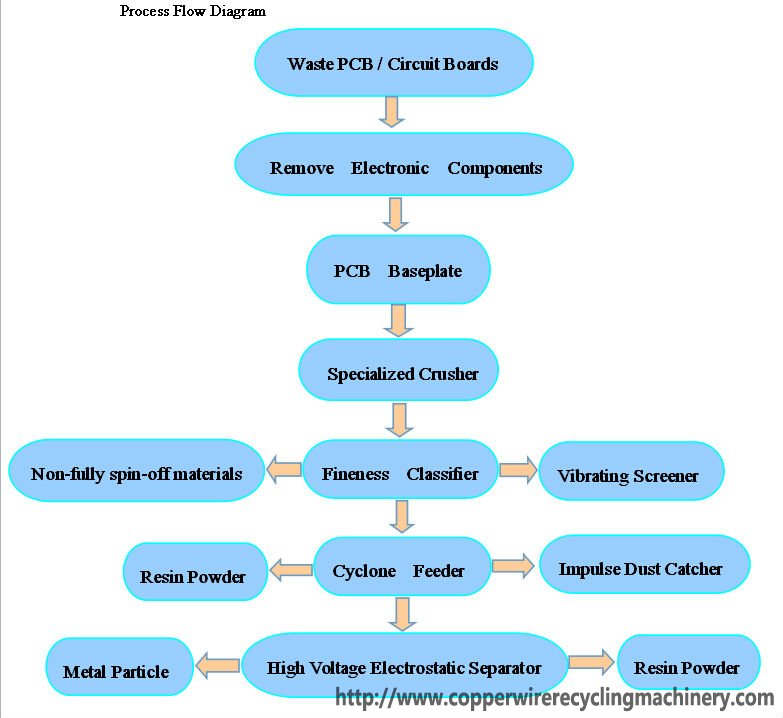

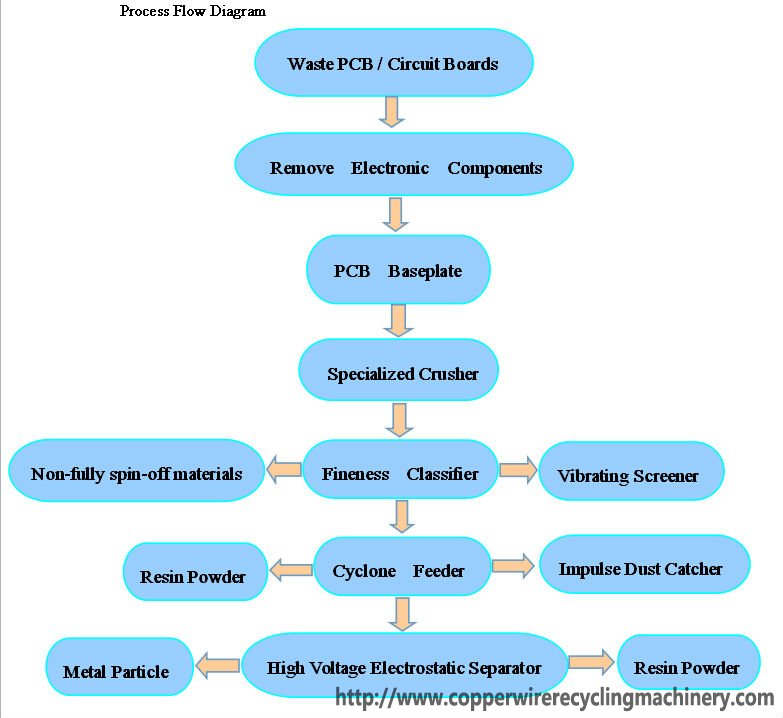

3.Flow chart of Circuit board separator machine

4.Raw material of Circuit board separator machine

4.Raw material of Circuit board separator machine

Circuit board separator application to this raw materials, such as(a)Computer motherboards, Cell phone boards, Tv Boards, Freezer boards,Air-conditioner boards, Radio Boards, Printer boards, overleft of pcb , Coated copper plate/copper clad laminate.

5.Technical data of Circuit board separator machine

5.Technical data of Circuit board separator machine

Circuit board separator machine

2.Advantage of Circuit board separator machine

Circuit board separator machine

2.This dust removal equipment has three-stage dust removal: cyclone dust removal, bag dust removal and dust removal by air cleaner;

3.All of these effectively solve the problem of dust pollution with every index up to the national standard.

4.Saving motive power and human power

5.Without Wastes.

3.Flow chart of Circuit board separator machine

Circuit board separator application to this raw materials, such as(a)Computer motherboards, Cell phone boards, Tv Boards, Freezer boards,Air-conditioner boards, Radio Boards, Printer boards, overleft of pcb , Coated copper plate/copper clad laminate.

| Model | Voltage | Power | Capacity | Dimension | Weight |

| DYTM-400 | 380V | 22.45 kw | 150-200kg/H | 2700*1900*2300(mm) | 1200kg |

| DYTM-600 | 380V | 36 kw | 300-400kg/H | 3500*1900*2700(mm) | 3000kg |

| DYTM-800 | 380V | 75 kw | 500-600kg/H | 5500*4500*3300(mm) | 8000k |