PCB board separation machine

Product

- Copper wire granulator machine

- Cable Wire Recycling Copper Separating Machine

- Cable recycling machine

- Professional Copper Cable Wire Recycling machine

- Copper cable separation

- Scrap copper wire recycling equipment

- High recycling rate of PCB Recycling Machine

- Waste Cable Recycling Copper Machine

- Scrap Copper granulator Cable wire Recycling Machine

- China manufacturers copper wire waste recycling machine

- Circuit board separator machine

- Recycling circuit board machine

- Waste circuit board recycling equipment

- 2015 china best circuit board recycling machine/waste PCB recycling equipment with factory price

- Manufacture PCB recycling plant

- PCB board separation machine

- Circuit board recycling equipment

- Eco-friendly E-waste recycling plant

- Advanced technology circuit board recycling machine

- 2015 hottest PCB recycling machine

- Aluminum plastic tube separation equipment

- Aluminum separating eauipment

- Aluminum cans recycling machine

- Aluminum separation machine

- Separation aluminum and plastic recycling machine

- Aluminum recycling machine

- Machine manufacturers waste aluminum plastic separator

- Aluminum recycling equipment

- Waste aluminum plastic separation

- supplier waste aluminum plastic separator

News

This type PCB board separation machine (high voltage electrostatic separation type) adopts a process route that makes raw materials such as printed circuit boards to be a mixture of metal and resin fiber powder by dry crushing and pulverization and then separates the metals from the non-metal materials such as resin by high voltage electrostatic separator. To avoid dust pollution in the process, the equipment also uses the three-in-one dust removal equipment. This dust removal equipment has three-stage dust removal: cyclone dust removal, bag dust removal and dust removal by air cleaner. All of these effectively solve the problem of dust pollution with every index up to the national standard.

This PCB board separation machine has a great capacity production and low consumption. And the copper purity of recycling is more than 99.99%.

PCB board separation machine

Application of PCB board separation machine

The PCB board separation machine can be used for recycling all kinds of circuit boards, computer board, TV board, aluminum-plastic plate, copper board, printed circuit boards etc. the metal recovery rate can be up to 99.9%.

| Model |

Power (kw) |

Capacity (Kg/h) |

Demission (mm) |

Efficiency separation |

Weight (kg) |

| DYPCB-300 | 80 | 300 | 8300*5300*4640 mm | 97-99% | 5000 |

| DYPCB-500 | 140 | 400-500 | 21200*4050*5420 mm | >99% | 17000 |

| DYPCB-800 | 185 | 700-800 | 26850*4050*5420 mm | >99% | 21000 |

| DYPCB-1000 | 255 | 900-1000 | 27000*5600*4750 mm | >99% | 25000 |

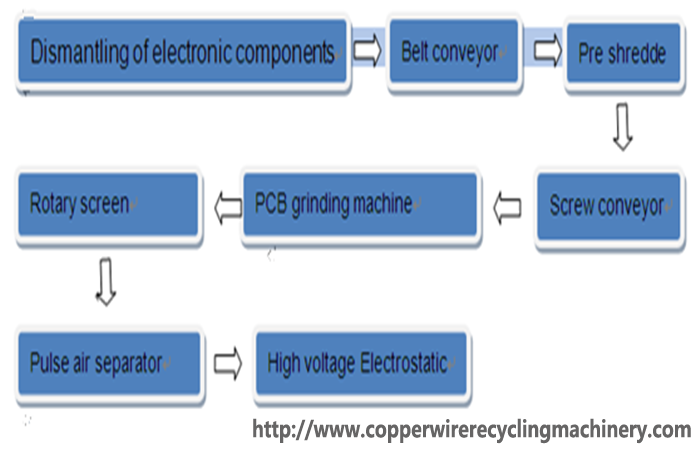

Flow diagram of PCB board separation machine

PCB board separation machine

Features ofPCB board separation machine

1.New process of advanced mechanical pulverization and high voltage electrostatic separation is adopted so that the purity of metal and non-metal separated after crushing and dissociation is high.

2.The unit consumption of energy to treat one ton of waste and used printed circuit board is only about 3/5 of that of domestic product alike; the largest treatment capacity of one set of equipment is 1 ton per hour.

3.Low cost pcb milling machine has good comprehensive performance, having special effect on computer board, calculator board, TV board and other control printed circuit board, and compatibility for recovery of various circuit boards with capacitor components.

4.This PCB board separation machine is an upgraded and renewed product of wind-separated products, which consumes less power than wind-separated type and has no noise.

5.PCB board separation machine needs fewer operators and has no pollution and noise. Besides, the equipment is flexible for layout.