WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Considering the standard composition as follow, when processing 1 ton of waste lithium batteries, we could potentially recover approximately 250 kilograms of cobalt, 100 kilograms of nickel, 70 kilograms of manganese, 60 kilograms of lithium, and 120 kilograms of copper.

To understand what we can get from processing 1 ton of waste lithium batteries, it is necessary to consider the battery type and specific design. Generally, a lithium battery is composed of several critical materials including lithium, cobalt, nickel, manganese and graphite among others. Moreover, other elements, though present in smaller proportions, would also contribute significantly to the recoverable resources. The proportion of these components essentially determine what can be obtained from the recycling process.

Waste lithium batteries

Waste lithium batteries

A standard composition of a lithium battery can be defined as follows: about 25 % cobalt, 10% nickel, 7% manganese, 6% lithium and around 12% copper. Additionally, various other elements like aluminum, iron, Silicon and semi-valuable metals also form part of the composition on a smaller scale.

It's critical to note that, the recoverable amount could also vary depending on the efficiency of the recycling process and technologies. Traditional recycling technologies are dominated by pyrometallurgical methods with the aim of extracting valuable metals. However, it also has shortcomings such as high energy costs and relatively poor lithium recovery rates. Alternatively, hydrometallurgical methods use chemical solutions to dissolve and separate valuable metals, offering the potential for higher recovery rates but facing the challenge of managing remaining waste liquids.

Here, DOING explores a new method that combines mechanical and pyrolysis - a lithium battery recycling plant - to provide more efficient recycling and less pollution. These processes of lithium battery recycling plant are expected to significantly increase the recycling ratio compared to traditional methods.

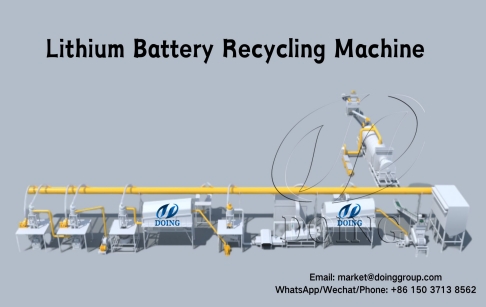

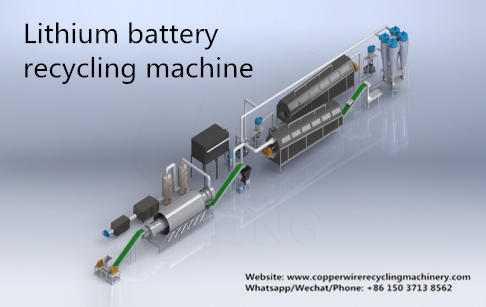

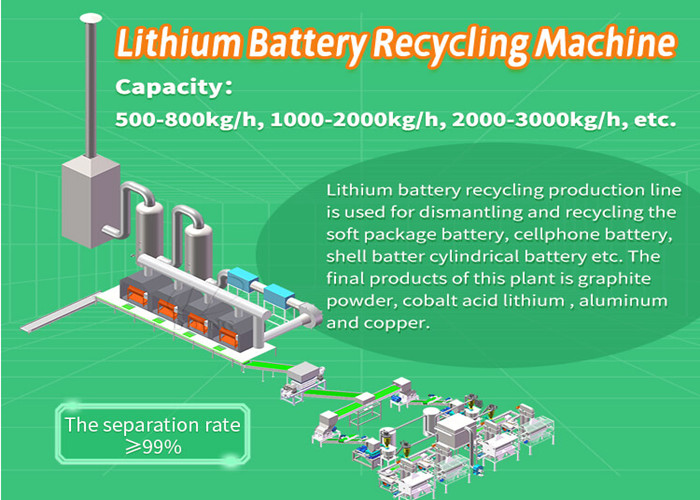

Lithium battery recycling plant

Lithium battery recycling plant

DOING lithium battery recycling plant integrates a series of equipment such as shredding, crushing, crushing, multi-stage sorting, pyrolysis, fine crushing, and re-sorting. Lithium battery recycling plant uses mechanical multi-stage crushing and sorting methods to extract nickel, cobalt, lithium copper, etc. from wasted batteries to obtain recycled materials for battery production. And it also improves the recovery rate of graphite powder on battery current collectors and increases the recycling value of waste batteries.

Final products

Final products

The potential and profit of recycling waste lithium battery is a huge. DOING company as lithium battery recycling plant manufacturer, we will provide the best service and quality machine. If you are interested in lithium battery recycling business , you can come to our factory with your materials to check the machine.