WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

As lithium-ion batteries become increasingly prevalent in our daily lives, the number of end-of-life lithium batteries is increasing, and the need for cost-effective and sustainable recycling methods has never been more important.

The disposal methods for waste lithium batteries are cascade utilization and disassembly and recycling. Cascade utilization refers to the testing, screening, and reorganization of waste lithium batteries so that they can continue to be used in other fields, such as energy storage systems, electric bicycles, etc. This method can effectively extend the service life of the lithium batteries and reduce resource waste. Disassembly recycling is to disassemble waste lithium batteries, extract valuable metal elements such as lithium, cobalt, and nickel, and then further process them to make new batteries or other products.

The value of recycling waste lithium batteries is mainly reflected in two aspects: one is environmental protection, and the other is resource conservation. At present, some advanced recycling technologies have been applied to lithium battery recycling machine, which can efficiently disassemble and recycle lithium batteries and bring considerable profits.

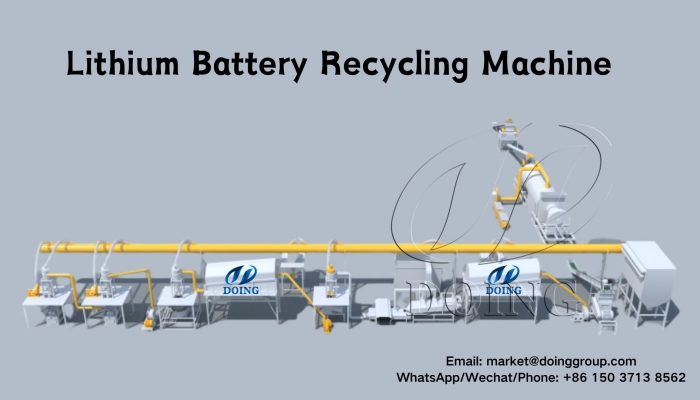

Lithium battery recycling machine

Lithium battery recycling machine

DOING lithium battery recycling machine uses oxygen-free pyrolysis, multiple crushing and physical screening technologies to separate black mass, copper, aluminum and diaphragm by processing waste lithium batteries. Besides, our lithium battery recycling machine has a wide range of applications, and the materials that can be processed include electric vehicle batteries, soft-pack batteries, mobile phone batteries, steel-shell lithium batteries, aluminum-shell batteries, cylindrical lithium batteries, lithium battery positive and negative electrodes, etc.

Raw materials

Raw materials

The discharged lithium batteries are sent to the lithium battery crusher through a conveyor for coarse crushing. This step will initially separate the battery shell from the internal materials. Next, these materials enter the high-temperature pyrolysis stage. By controlling the temperature and time, the organic matter inside the battery is decomposed to further release valuable components. The pyrolyzed material is then sent to the crusher for further crushing, and the drum screen screens out the black powder. At this stage, the screening rate of black powder is about 70%-80%. The remaining materials enter the secondary crusher and grinder for fine crushing, and the copper and aluminum powder in the materials are separated by gravity separator and other screening machine. The whole process is equipped with multi-stage black powder collectors to ensure a high recovery rate of black powder.

1. Multifunctional integrated equipment: Develop multifunctional integrated lithium battery recycling machine to achieve integrated integration of multiple links such as feeding, crushing, pyrolysis, and sorting. This can reduce the equipment footprint, improve production efficiency, and reduce equipment investment costs.

2. Efficient sorting technology: New magnetic separation and airflow separation technologies are used to improve the recovery rate and purity of metals. Both the drum screen and the circular vibrating screen are equipped with carbon black collectors, and the black powder collection rate is high.

Lithium battery recycling machine

Lithium battery recycling machine

3. Intelligent control: Use advanced automatic control technology to realize intelligent operation and monitoring of equipment. By real-time monitoring and adjusting process parameters, the stability and reliability of equipment can be improved, and the difficulty of operation and labor costs can be reduced.

4. Environmental protection treatment technology: The entire production line operates under negative pressure, that is, all materials are sucked in, without dust pollution. Equipped with a complete exhaust gas treatment system to ensure that national emission standards are met and achieve green and environmentally friendly production.

Since cobalt and lithium are required to manufacture lithium-ion batteries, the lithium-ion battery recycling market will continue to grow as demand for these metals increases. Our lithium battery recycling machines are designed to help you recover valuable materials efficiently, reduce waste, and maximize profits. If you are interested and want to learn more specific details, please feel free to contact us.