WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Carbonization equipment is an environmentally friendly device specially used to convert biomass raw materials into high-quality charcoal. It converts organic materials such as wood and bamboo into solid fuel charcoal through a dry distillation carbonization process under high temperature and oxygen-free conditions. Carbonization equipment can be classified into horizontal equipment carbonization equipment and vertical carbonization furnace.

Biomass carbonization

Biomass carbonization

When consulting charcoal manufacturing equipment, many people will ask what is the difference between horizontal pyrolysis carbonization equipment and vertical carbonization furnace? Are their carbonization processes the same? Next, let the editor solve the puzzle for everyone!

There are significant differences between horizontal pyrolysis carbonization equipment and vertical carbonization furnace in structure, process flow, production efficiency, etc. The following is a detailed comparative analysis:

1.Structural design

Horizontal pyrolysis carbonization equipment usually adopts a drum structure, such as a continuous carbonization furnace. This structure allows the material to be evenly heated during the carbonization process and improves the carbonization efficiency.

Carbonization equipment

Carbonization equipment

Vertical carbonization furnace usually adopt a hoisting structure, such as a hoisting dry distillation carbonization furnace. This structure enables materials to be stacked vertically during the carbonization process, which is convenient for loading and unloading and maintenance.

But the vertical carbonization furnace has a small heating area and is always heated from the bottom. It is not as efficient and durable as the horizontal type and has a long service life;

2.Process Flow

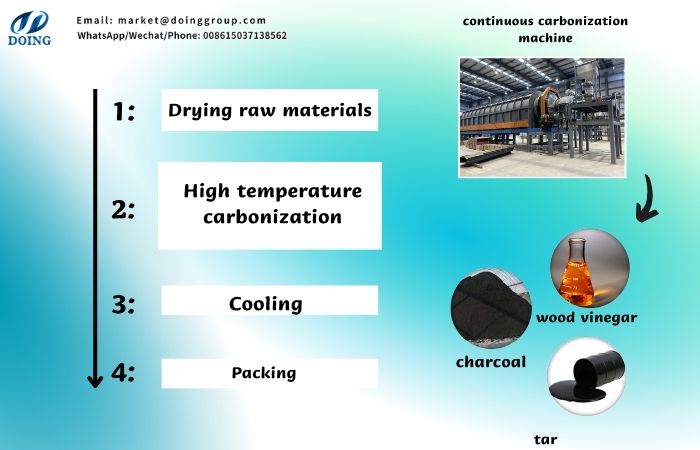

The process of horizontal pyrolysis carbonization equipment is a complex process. The following are the specific steps of the horizontal pyrolysis carbonization equipment process:

①Crushing and pre-treating biomass raw materials (such as sawdust, rice husks, etc.) to improve carbonization efficiency.

②Send the crushed materials into the drying furnace to remove moisture from the raw materials.

③The dried materials enter the continuous carbonization furnace for pyrolysis reaction to form high-quality charcoal.

Process of horizontal pyrolysis carbonization equipment

Process of horizontal pyrolysis carbonization equipment

The combustible gas generated during the carbonization process is collected and sent back to the furnace of the carbonization furnace as fuel, which saves energy and reduces environmental pollution. Henan DOING horizontal carbonization furnace is equipped with an advanced PLC control system, which can accurately control the carbonization time and temperature. It not only improves production efficiency, but also ensures the stability of product quality.

Vertical carbonization furnaces usually adopt direct heating, and the heat generated by fuel combustion is directly transferred to the carbonized material to eventually form charcoal.

In comparision, the process setting of the horizontal carbonization equipment is more sophisticated, and different equipment configurations can be adjusted according to different material requirements, and the processing effect is more ideal.

3.Production efficiency

Horizontal carbonization equipment

Horizontal carbonization equipment

The processing capacity of vertical carbonization furnaces is small, and the specification types are limited. The horizontal type generally has a larger processing capacity and can be customized. Beides that, horizontal pyrolysis carbonization equipment can achieve higher production efficiency due to its automatic control and continuous production characteristics.

4.Energy Consumption

The vertical carbonization furnace is not equipped with a combustible gas recovery device, while the horizontal carbonization equipment is equipped with a combustible gas recovery device, which is more energy-saving and has better long-term benefits;

5.Application field

In large-scale industrial production, the high production capacity of horizontal pyrolysis carbonization equipment is particularly prominent, with a single-hour production capacity of 1 ton to 5 tons, and a daily processing capacity of even tens or hundreds of tons. The continuous feeding and discharging design of the horizontal pyrolysis equipment, combined with precise temperature control and combustible gas recovery system, meets the dual needs of large-scale production for efficiency and quality.

Horizontal carbonization equipment

Horizontal carbonization equipment

In small-scale processing or family carbonization operations, vertical carbonization furnaces are more suitable. The investment cost of vertical carbonization furnaces is relatively low, and the footprint is small, which is very suitable for small-scale entrepreneurs' carbonization business.

In short, vertical and horizontal carbonization furnaces each have their own applicable processing scenarios and characteristics. You can choose the right carbonization equipment according to your personal situation! As a horizontal carbonization equipment manufacturer with more than ten years of history, Henan DOING's engineers and sales team are willing to assist you in customizing effective pyrolysis carbonization equipment. If you are interested in our pyrolysis carbonization equipment, please contact us immediately.