WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

The waste lithium-ion battery recycling business has received favor from many investors due to its considerable economic benefits. In recent years, there are three main lithium-ion battery recycling methods that are well-known on the market: 1. Fire method, 2. Water method, and 3. Lithium-ion battery recycling equipment. Next, the editor of DOING will explain to you the relevant specific lithium battery recycling processes, and compare their respective characteristics to help you find the most suitable lithium battery recycling method.

Lithium-ion battery

Lithium-ion battery

Fire recycling mainly uses discharge disassembly and then high-temperature treatment. However, the energy consumption and emissions of the fire method are very high. In addition, the pollution is also very large.

The water method recycling mainly uses chemical reagents to refine the metal and turn it into oxides. However, the water method is relatively polluting and time-consuming. Is there a better way?

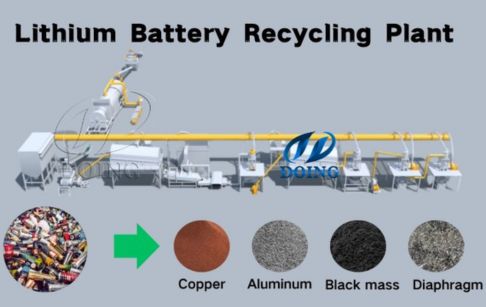

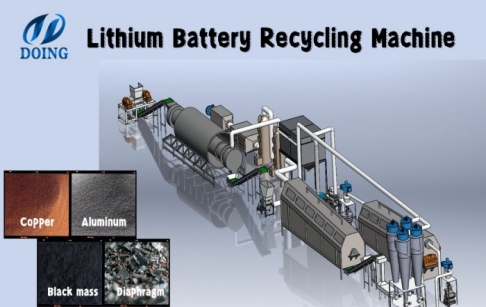

DOING lithium-ion battery recycling equipment mainly separates these highly valuable products through the processes of discharge, shredding, carbonization, crushing and screening.

Lithium battery recycling machine

Lithium battery recycling machine

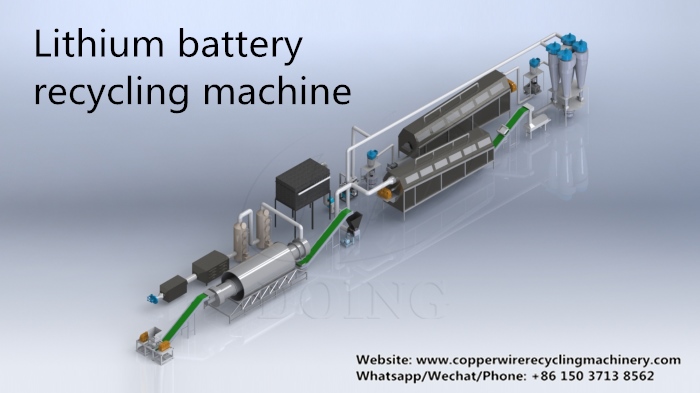

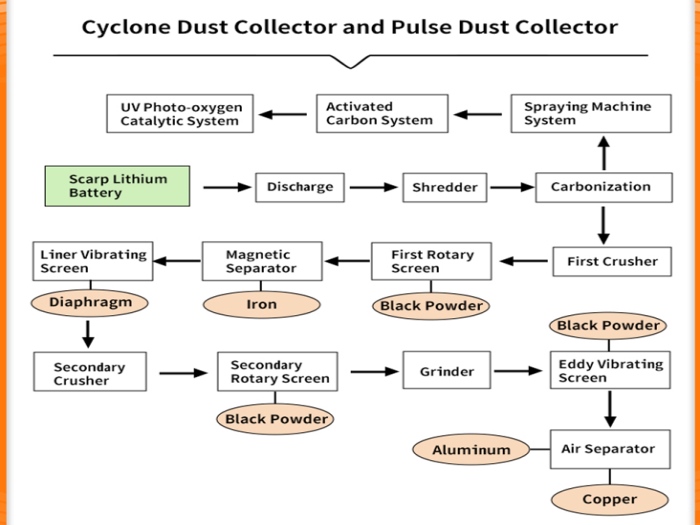

First, soak the used lithium battery in sodium chloride solution to short-circuit the positive and negative electrodes of the battery, thereby completely discharging the battery. Avoid short circuits and fires during crushing and sorting processes. Then send the discharged lithium battery to the double-shaft shredder. The fragments are further broken down. Then enter the carbonization process. By heating the battery residue in a low-oxygen or oxygen-free environment, organic matter is converted into carbon-like substances. Carbonization helps convert battery residue into high-purity carbon materials that can be reused in battery production or other industrial applications.

The crushed lithium battery fragments enter the magnetic separator, which uses magnetic attraction to separate the iron. The crushed particles fall into separation equipment such as linear vibrating screens, trommel screens, and air flow separators, which use the size and shape differences between particles as well as the differences in particle weight to efficiently separate copper, aluminum, and black substances.

Lithium battery recycling machine working process

Lithium battery recycling machine working process

DOING lithium-ion battery recycling equipment is equipped with systematic processing machines including shredders, pulverizers, rotary vibrating screens, air flow separators, etc., to efficiently separate the recycled products. In addition, it is also equipped with a spray tower system, activated carbon system and UV photooxygen catalytic system to remove dust and odor, and the recycling process does not cause any pollution.

In waste recycling stations, we often see various kinds of used lithium-ion batteries, including power lithium batteries, steel case lithium batteries, mobile phone lithium batteries, plastic case lithium batteries, soft-pack lithium batteries, aluminum case lithium batteries, etc. The positive electrodes in these lithium-ion batteries contain high-priced resources such as cobalt, lithium, aluminum foil, and copper foil, which have extremely high recycling value. This is why DOING launched lithium-ion battery recycling equipment.

Lithium battery

Lithium battery

DOING lithium-ion battery recycling equipment adopts advanced mechanical crushing and new screening and separation processes. High sorting purity. The key technology of our equipment is the organic combination of special crushing and dissociation equipment for lithium-ion batteries to maximize the energy-saving effect.

If you encounter problems during the lithium-ion battery recycling process, and if you want to know the price, recycling volume and other information related to our lithium-ion battery recycling equipment, you can contact us at any time at your convenience. We will answer your questions.