WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Copper and aluminum scrap radiator recycling plant is a set of professional crushing and separation line, which can be used to process all kinds of scrap radiators from air conditioner, car water tank, cold storage, etc. And it can easily separate copper, aluminum and iron. At the same time, copper and aluminum scrap radiator recycling plant can make the waste resources reused again, supported by government in each countries.

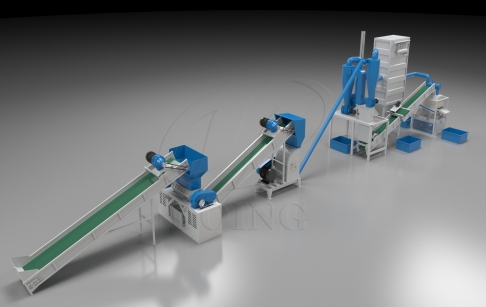

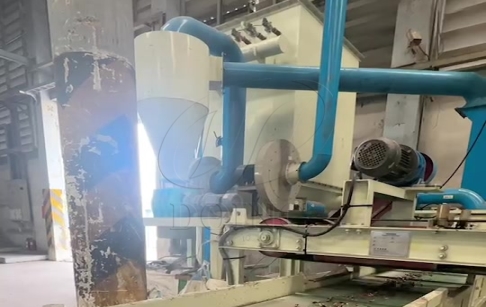

Copper and aluminum scrap radiator recycling plant

Copper and aluminum scrap radiator recycling plant

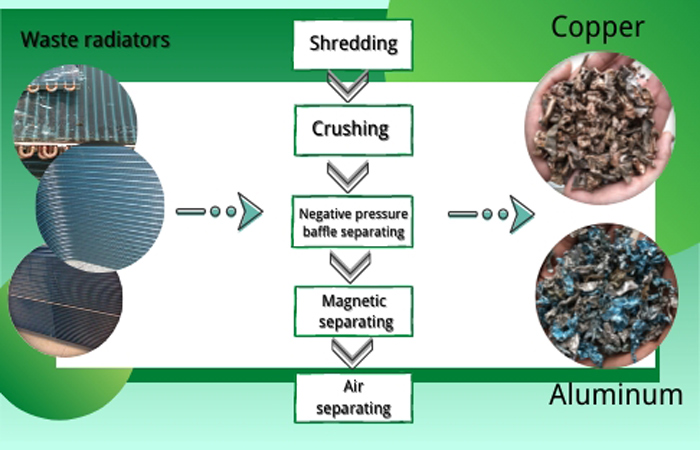

Shredding -- crushing -- negative-pressure baffle separation -- magnetic separation -- air separation

Working process of copper and aluminum scrap radiator recycling plant

Working process of copper and aluminum scrap radiator recycling plant

Here, we’ll introduce the working process of copper and aluminum scrap radiator recycling plant in details, for you to better understand.

Step 1: Shredding and crushing

Shredder will shred the scrap radiator into 5-7cm particles, that’s a pre-cut process. Then the crusher will further crush the materials into 2-3cm, here the copper and aluminum will be crushed separately. And there is screen in the bottom of crusher, so it can control the size of copper and aluminum after crushed, thus to better for next processing of separation.

Step 2: Negative-pressure baffle separation

Negative-pressure baffle separation system is our unique and special technology. It can separate most of aluminum out first, thus to improve efficiency in the whole process. Furthermore, it will be benefit for air separator to separate the left aluminum and copper then in the following process.

Step 3: Magnetic separation

As we know, magnetic separation process is to remove iron from the other metals, thus to protect the final products value.

Step 4: Air separation

At last, air separation process will separate the left aluminum and copper by different gravity. Finally the separation rate could be reaching to 99%.

So after processed by copper and aluminum scrap radiator recycling plant, the final products you can get will be pure copper, pure aluminum and pure iron, which can be sold directly to earn profit after recycling.

The following is the profit analysis table. You can learn about it.

| Running cost / Day | |||||

| Item | Input | Quatity | Unit Price ($) | input cost ($) | total cost($) |

| 1 | Waste radiators | 500kg/h*8h=4T | 3100 | 12400 | 12513.72 |

| 2 | Power consumption | 62Kw/H*8H=496KwH | 0.14 | 70.86 | |

| 3 | Workers | 2 workers | 21.42/day | 42.86 | |

| Income/day | |||||

| Item | Output | Quantity | Price($) | Income($) | Total income($) |

| 1 | Copper | 4T*53%=2.12T | 3500/T | 7420 | 15844 |

| 2 | Aluminum | 4T*45%=1.8T | 1050/T | 8424 | |

| Daily profit = daily income - daily cost=15844-12513.72=3330.28 ($) | |||||

Obviously, it is a very good investment project that using copper and aluminum scrap radiator recycling plant to recycle scrap radiators. Do you plan to start it?

Here, I summary the features about DOING copper and aluminum scrap radiator recycling plant. Hope it can help you to choose suitable equipment.

1. Can process almost all kinds of radiators and no need pretreatment;

2. 99% high separation rate to separate copper, aluminum and iron out;

3. With negative-pressure baffler separator technology, improve the accuracy of separation in the whole line;

4. With sealed wind conveyor and pulse dust collecting system, no dust fly around;

5. Fully automatic working, easy to operate.

If you have other special requirement, you can contact us for more details. Doing Company has engineers team, who can customize for you.