WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Many clients know how to operate the copper wire recycling machine, but do not know what the wearable parts of the copper wire recycling machine and how to maintain them. Now DOING will list the wearable parts of the copper wire recycling machine and tell you how to maintain them.

Copper wire recycling machine

Copper wire recycling machine

The wearable parts of the copper wire recycling machine contains blades of crusher, screens of crusher, belts, bearings and motors. Copper wire recycling machines are designed to separate copper from plastic and other materials, making it easier to recycle copper. However, like any other machine, copper wire recycling machines have wearable parts that need to be maintained to ensure optimal performance. Here are some tips on how to maintain them:

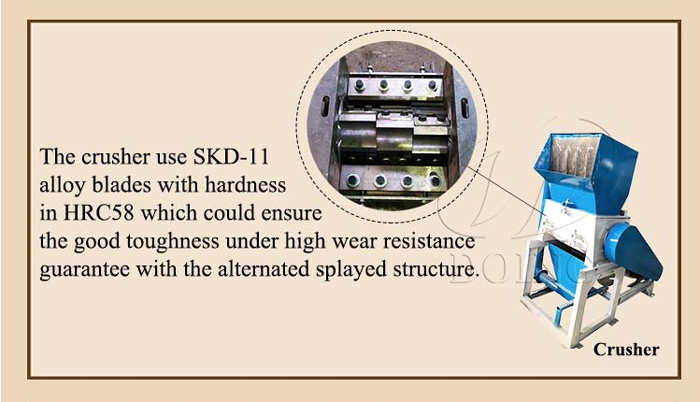

During the copper wire recycling machine running, you need to pay attention to checking whether the crusher blade is damaged. If a large amount of material cannot be broken, it indicates that the blade needs to be ground or replaced.The blades are one of the most important wearable parts of the copper wire recycling machine. They are responsible for cutting and separating the copper wires from the plastic insulation. Over time, the blades can become dull or damaged, which can affect the copper wire recycling machine’s performance. To maintain the blades, they should be sharpened regularly or replaced when necessary. You can take out of the whole blades, replace the blades one by one. It is also important to clean the blades after each use to prevent buildup and corrosion.

Crusher

Crusher

Screens are responsible for separating the copper wires from the plastic insulation. Over time, screens can become clogged or damaged, which can affect the copper wire recycling machine's performance. When process different kinds of waste cable wires, the screen size will be 3mm, 4mm, or 5mm. Also when it was broken, the screen will be Leakage of materials. To maintain the screens, they should be cleaned regularly and inspected for signs of wear or damage. If any issues are found, the screens should be replaced immediately. When take place of the screen of crusher, you need to open the hopper at the bottom of the crusher and pull out the screen.

Belts are another wearable parts of the copper wire recycling machine. They are responsible for transferring power from the motor to the blades and other moving parts. Over time, belts can become worn or damaged, which can cause the machine to malfunction. To maintain the belts, they should be inspected regularly for signs of wear or damage. If any issues are found, the belts should be replaced immediately.

Bearings are also the wearable parts of the copper wire recycling machine. It is responsible for supporting the moving parts of the copper wire recycling machine. Over time, bearings can become worn or damaged, which can cause the copper wire recycling machine to vibrate or make unusual noises. To maintain the bearings, they should be lubricated regularly and inspected for signs of wear or damage. If any issues are found, the bearings should be replaced immediately.

We need to note that the motors are also one of the wearable parts of the copper wire recycling machine. Motors are responsible for powering the copper wire recycling machine. Over time, motors can become worn or damaged, which can cause the machine to malfunction. To maintain the motors, they should be inspected regularly for signs of wear or damage. If any issues are found, the motors should be replaced immediately.

In conclusion, copper wire recycling machines have wearable parts that need to be maintained to ensure optimal performance. By regularly inspecting and maintaining the blades, belts, bearings, screens, and motors, you can ensure that your copper wire recycling machine operates at peak efficiency and lasts for years to come.

Factory

Factory

The composition of the copper wire recycling machine, the quality of the blades and the precision of the spindle components have a direct impact on the separate rate of the copper and plastic. DOING copper wire recycling machine has high precision and high technical content characteristics of environmentally friendly equipment. It is the insistence on high quality that has made DOING copper wire recycling machine a leading brand in the industry and has been recognised by many clients.

DOING has been the copper wire recycling machine manufacturer for over 13 years. we have been exporting machine to 60 countries and have our own engineers and technical departments. So you need not to worry the after seals service. If you are interested in copper wire recycling machine feel free to contact us.