WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

In Thailand, setting up a smokeless charcoal making plant is a potential business project.With the increasing awareness of environmental protection and the growing demand for clean energy, the smokeless charcoal making plant has broad prospects. The following is a detailed introduction on how to successfully set up a smokeless charcoal making plant in Thailand.

1. Preliminary research on smokeless charcoal making plants in Thailand

a. Market demand analysis

Local market: Thailand has a developed catering industry, especially barbecue and hot pot, which have a large demand for charcoal. At the same time, with the development of tourism, tourists' pursuit of special barbecue experience has further promoted the demand for charcoal.

International market: Thailand has a superior geographical location and convenient transportation, and has the advantage of exporting smokeless charcoal to neighboring countries and international markets. For example, some European and American countries have a growing demand for environmentally friendly smokeless charcoal and are willing to pay a higher price.

Smokeless charcoal making plant in Thailand

Smokeless charcoal making plant in Thailand

b. Policy and regulatory research

Investment policy: The Thai government has introduced a series of preferential policies to attract foreign investment. For example, industrial parks established in specific areas may provide tax exemptions, land concessions and other policies.

Environmental regulations: Set up a smokeless charcoal making plant must strictly comply with Thailand's environmental regulations. During the production process, it is necessary to ensure that the emissions of waste gas, wastewater, waste residue, etc. meet the standards. For example, for the waste gas generated during the carbonization process, DOING installs effective flue gas purification equipment to meet Thailand's environmental protection standards. At the same time, in the early stage of project construction, an environmental impact assessment (EIA) may be required and approval from relevant departments may be obtained.

c. Raw material supply assessment

Raw materails of smokeless charcoal making plant in Thailand

Raw materails of smokeless charcoal making plant in Thailand

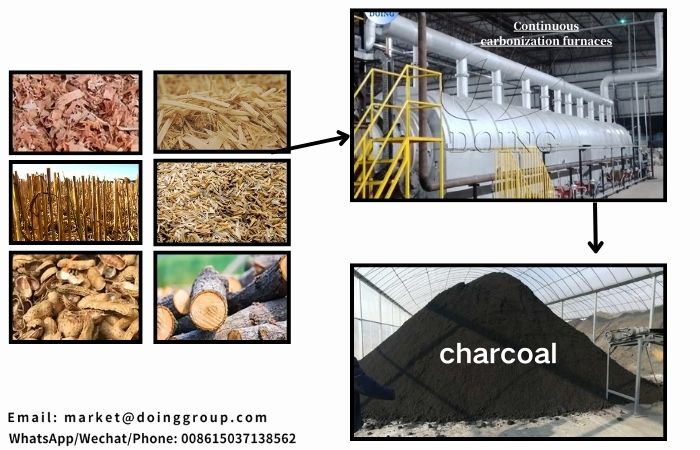

Local raw material resources: Thailand has abundant biomass resources, such as coconut shells, rice husks, bagasse, corn stalks, coffee shells, palm shells, etc., which are high-quality raw materials for making smokeless charcoal. DOING helps Thai customers set up coconut shell smokeless charcoal making plants. Thailand is one of the main coconut planting areas, and a large amount of waste coconut shells are produced every year, with a wide range of sources and relatively low costs.

2. Smokeless charcoal making plant site and equipment selection in Thailand

a. Site selection

Close to raw materials and markets: Try to choose industrial parks close to raw material supply and product sales markets. If the raw materials mainly rely on local supply, being close to the raw material production area can reduce transportation costs; if the products are mainly sold to the local market, being close to the consumption area can improve distribution efficiency. In addition, consider the distance between the site and logistics hubs such as ports and airports to facilitate future import and export business. DOING provides pre-sales services and can help you choose a suitable smokeless charcoal making plant address.

b. Equipment selection

DOING smokeless charcoal making machine in Thailand

DOING smokeless charcoal making machine in Thailand

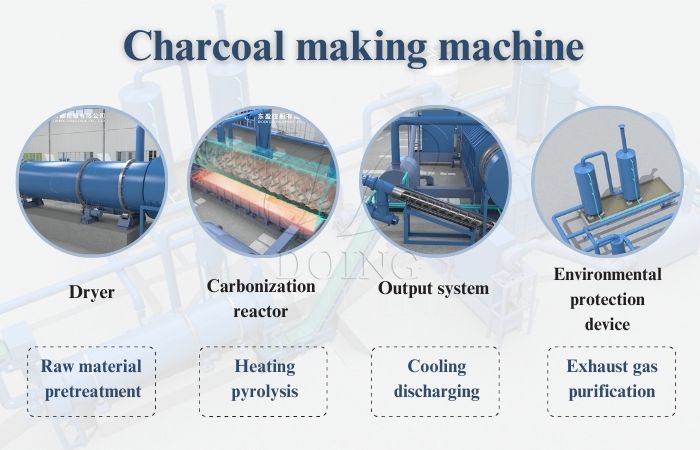

Advanced production equipment: Investing in advanced smokeless charcoal production equipment is the key to ensuring product quality and production efficiency. DOING smokeless charcoal making machine is equipped with a crusher, dryer, carbonization furnace, water cooler, and flue gas purifier. It adopts a PLC control system, which can accurately control the carbonization temperature and time, reduce manual intervention, and improve product quality stability. Compared with traditional charcoal furnaces, it has the advantages of environmental protection, high efficiency, and uniform carbonization.

3. Smokeless charcoal making plant production process in Thailand

a.Smokeless charcoal production process

Raw material pretreatment: Determine whether it needs to be crushed and dried according to the particle size and moisture of the raw material. For larger raw materials, such as coconut shells, crush them into particles below 30mm through a crusher; if drying is required, transport them to a drum dryer to reduce the moisture to below 15%, and then send them to the carbonizer to reduce the load of the carbonizer.

Smokeless charcoal making machine in Thailand

Smokeless charcoal making machine in Thailand

Carbonization process and heat energy utilization: Use external heat sources such as burners to heat the carbonization furnace, and the raw materials are dried, dehydrated, and carbonized in the carbonization furnace to produce combustible gas. After purification and separation, the combustible gas is sent to the combustion chamber by the induced draft fan for combustion. The hot gas generated is used to heat the carbonization host, and the residual heat is introduced into the dryer to dry the material. The exhaust gas after drying is discharged after being treated by the shaklon dust removal and tail gas purification tower.

Utilization of pyrolysis gas and adjustment of carbonization machine: After the pyrolysis gas is generated, the burner can be gradually turned off and self-produced pyrolysis flue gas can be used for heating (external heat source is supplemented when the pyrolysis gas is insufficient). The carbonization machine is equipped with a variable frequency speed regulating motor, which can adjust the cylinder speed at any time to control the carbonization temperature and time of the material.

Water cooling device of DOING charcoal making machine

Water cooling device of DOING charcoal making machine

Finished product processing and cooling water circulation: After the carbonized finished product is fully cooled by cooling and conveying, it is sent to the material yard or silo for packaging or storage. The cooling water of the cooling system is cooled by the cooling tower and recycled by the water pump.

4. Operation and management of smokeless charcoal making plant in Thailand

a. Human resource management

Technical training of DOING Smokeless charcoal making plant

Technical training of DOING Smokeless charcoal making plant

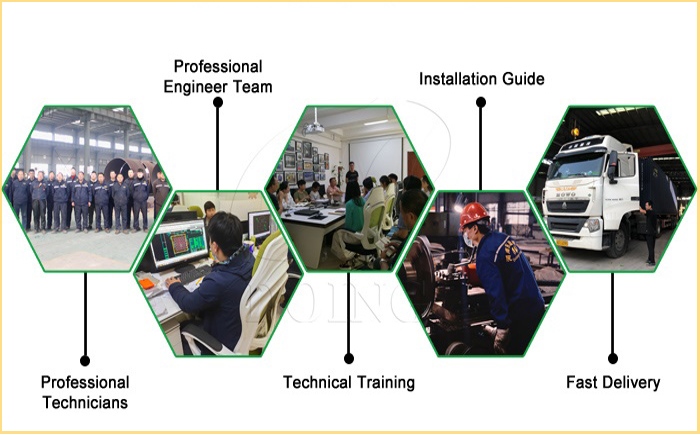

Employee training: Comprehensive training for new employees, including training on production process, equipment operation, safety knowledge, quality control, etc. DOING provides after-sales service and remote technical training, so that employees can master production technology, improve work efficiency and smokeless charcoal quality.

b. Cost control Cost control measures

In the raw material procurement link, establish a long-term and stable cooperative relationship with suppliers, and strive for more favorable prices and payment terms, reasonably arrange production plan.

c. Marketing strategy

Brand building and sales channels: Create a distinctive smokeless charcoal brand, and establish brand reputation by providing high-quality products and good after-sales service. For example, design unique product packaging to highlight the product's environmental protection, smokeless, high calorific value and other characteristics. Develop multiple sales channels. In addition to direct sales to catering companies, barbecue restaurants, etc., you can also consider cooperating with distributors and wholesalers to expand the sales scope of products. Use the Internet platform to carry out online sales, such as establishing an official corporate website, opening a store on an e-commerce platform, etc., to expand the customer base.

DOING smokeless charcoal making machine manufacturer

DOING smokeless charcoal making machine manufacturer

Setting up a smokeless charcoal making plant in Thailand requires full preparation in the early stage. From market research, policy and regulatory research to site equipment selection, production process optimization, and later operation management and marketing, each link is crucial. DOING has more than 14 years of experience in making smokeless charcoal equipment, which can help you quickly start a smokeless charcoal business in Thailand.