WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

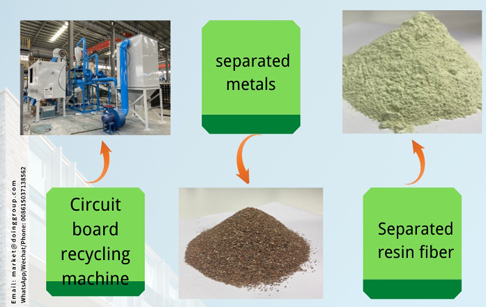

Printed circuit board recycling machine is a kind of e waste recycling machinery, which is specially designed for processing different waste circuit boards, such as printed circuit board, computer mother boards, mobile boards, copper clad laminate, circuit board scraps, etc. It can separate the precious metals from resin fiber for recycling use, and it can also destroy the data on the boards, to protect our privacy.

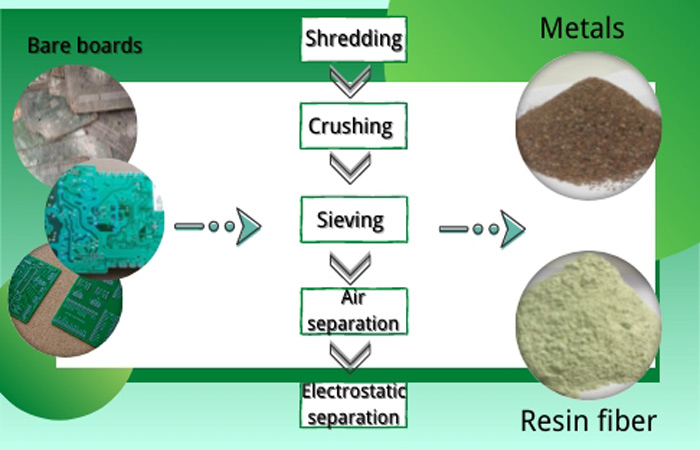

Shredding:

Use a shredder to shred the waste circuit boards into small pieces;

Crushing:

Use hammerhead crusher and hammer crusher to crush these pieces into small particles about 2-3mm;

Sieving:

Use an eddy-vibrating screen to control the size of particles - bigger particles will be stopped by eddy-vibrating screen and be sent back to the second crusher for further crushing;

Working process of printed circuit board recycling machine

Working process of printed circuit board recycling machine

Air separation:

Use an air separator to separate precious metals and resin fiber according to their different gravity;

Electrostatic separation:

Use an electrostatic separator to separate the precious metals mixed in resin fiber according to the conductivity of metal.

PCB dismantling machine

PCB dismantling machine

Tips: If there are electronic components on the waste circuit boards, a PCB dismantling machine, a supporting machine for printed circuit board recycling machine, can dismantle the electronic components from PCB base boards before crushing and separation process. The electronic components dismantled from PCB base boards could be collected and sold separately.

Final products and usage

Final products and usage

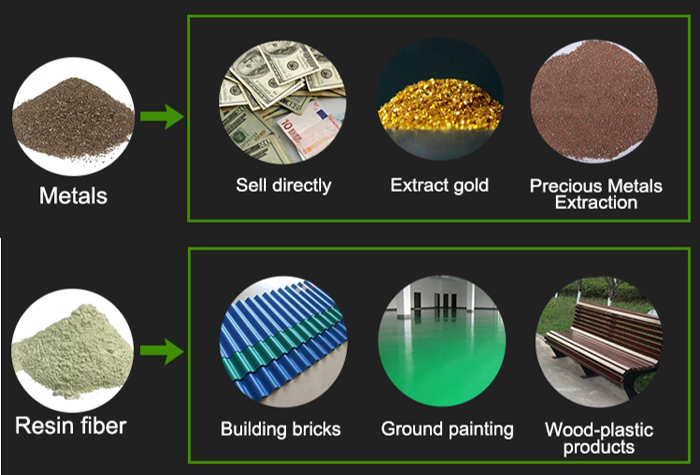

1. Precious metals: The separated mixed metals has 99% separation rate and good quality. They can be sold directly in the metal trading market at a pretty high price. Or they can be further processed to extract the precious metals and sell them.

2. Resin fiber: They can be made of resin tiles, ground painting, wood-plastic products, etc. If they are ground to about 300 mesh, they can also be used as heat and fire insulation materials.

| Capacity(Kg/h) | Overall Dimension | Power(Kw) | Weight(Kg) | Recovery Rate |

| 100-150kg/h | 8000*6000*4200mm | 42kw | 6000kg | ≥99% |

| 200-300kg/h | 10000*6000*4200mm | 76kw | 7500kg | |

| 400-500kg/h | 16000*8000*4200mm | 95kw | 8500kg | |

| 500-700kg/h | 21000*9000*4200mm | 140kw | 10000kg | |

| 800-1000kg/h | 24000*10000*4500mm | 250kw | 14000kg | |

| 1500-2000kg/h | 28000*20000*5000mm | 470kw | 19000kg |

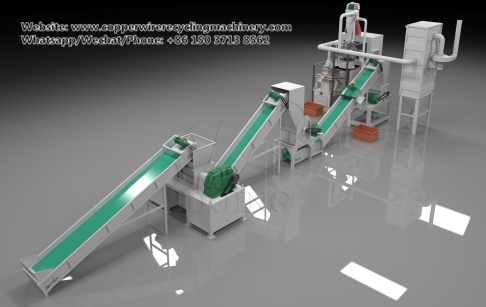

1. The whole PCB recycling process is controlled by PLC system, easy to operate, fully automatic;

2. Reasonable layout with compact structure, stable performance, low noise;

3. The crushing process include primary shredding and fine crushing with circulation water cooling to ensure the good performance;

4. Adopt negative pressure feeding system with pulse dust collector, which ensure no dust leakage and clean working environment;

5. The separation process adopts air separation and electrostatic separation methods, the separation rate of metals and nonmetals could reach to higher than 99%.

Deep information about the printed circuit board recycling machine, welcome your visit to DOING Company or contact us through our website.