WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Faced with an increasing amount of scrap lithium-ion batteries, battery recycling has become a crucial component of environmental protection and resource recovery. Lithium-ion battery recycling not only effectively reduces environmental pollution but also recovers valuable metals, achieving a circular economy. With fluctuating raw material prices and increasingly stringent environmental regulations, the economic benefits of battery recycling are gradually improving.

① Recycling scale is the primary determinant of economic viability. Large-scale centralized recycling facilities offer cost advantages due to economies of scale. By establishing standardized lithium-ion battery recycling production lines and optimizing process flows and equipment configuration, unit processing costs can be effectively reduced.

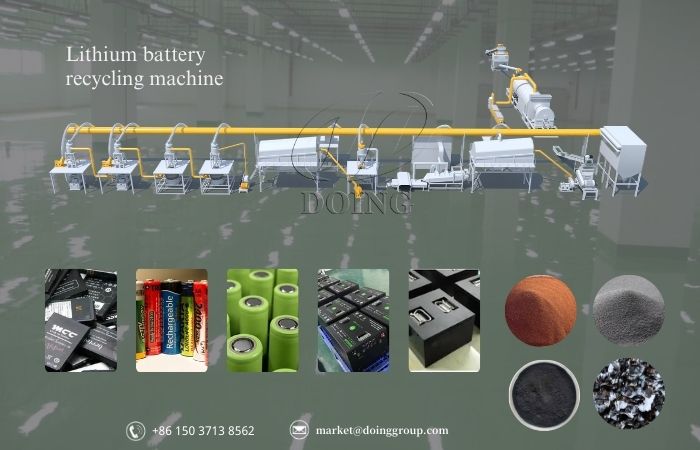

Large-scale lithium-ion battery recycling production line

Large-scale lithium-ion battery recycling production line

② Another important factor is the choice of battery recycling technology. Modern recycling technologies have already achieved high material recovery rates. These recovered materials can be directly returned to the supply chain and reused in the production of new batteries, thereby reducing the cost of new battery production.

Economical lithium-ion battery recycling not only contributes to sustainable business growth but also aligns with current environmental policy trends. By properly planning the recycling process, companies can transform used batteries into valuable resources and improve overall profitability. Choosing a professional and experienced lithium-ion battery recycling machine manufacturer is key to achieving economical recycling.

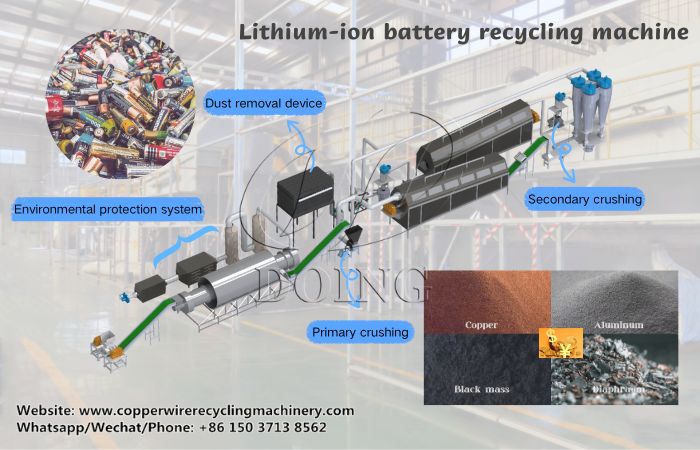

The DOING lithium-ion battery recycling plant utilizes a multi-stage crushing and sorting process, achieving a material recovery rate exceeding 98%. Furthermore, our automated crushing and sorting system extracts copper, aluminum, iron, black mass and plastics at industry-leading purity levels.

Automated lithium ion battery crushing and sorting system

Automated lithium ion battery crushing and sorting system

The PLC-controlled automation system minimizes manual operations. This reduces labor costs while ensuring stable 24/7 processing, maximizing output and significantly reducing the processing costs per ton.

Our battery recycling plants support large-scale lithium battery recycling, with capacity ranging from 500 kg/hour to 2,000 kg/hour. We can also customize recycling solutions to meet your needs, matching production capacity to your production volume to ensure maximum economic benefits.

DOING lithium battery recycling plant provides the most suitable recycling solution

DOING lithium battery recycling plant provides the most suitable recycling solution

As battery recycling regulations become increasingly stringent around the world, compliant processing procedures can help avoid potential environmental penalties. The DOING lithium-ion battery recycling plant utilizes a fully enclosed system to ensure safe processing throughout the entire process. Equipped with an exhaust gas treatment system, it effectively controls dust and hazardous gases, eliminating pollution fines and ensuring regulatory compliance.

With proper planning and access to professional battery recycling plant, lithium-ion battery recycling can be a viable, economical, and environmentally friendly initiative. Choosing the right partner can make this process efficient, compliant, and profitable. Contact us today for professional advice and customized solutions.