WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

It is estimated that millions of photovoltaic panels will reach the end of their life in the coming decades, and efficient and environmentally friendly recycling technologies are essential to recover valuable materials and reduce waste. Mechanical sorting, chemical decomposition, and pyrolysis are currently the main technologies for recycling photovoltaic panels. In this article, we will explore the best technology for recycling photovoltaic panels from three perspectives: effectiveness, environmental impact, and economic feasibility.

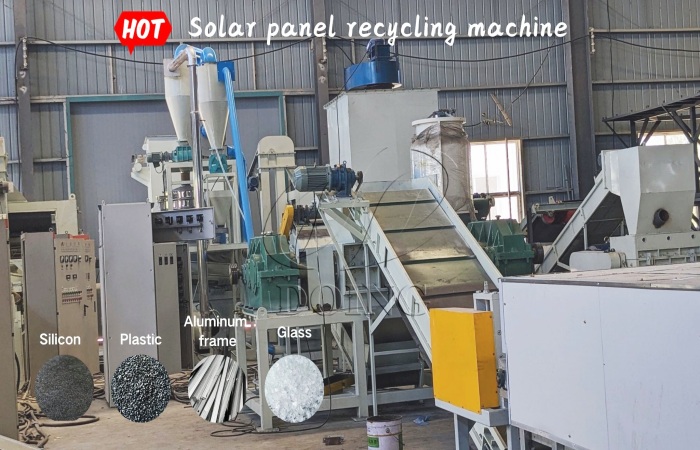

Mechanical sorting, also known as physical separation, is the most common technology for recycling Photovoltaic panel. It involves dismantling the photovoltaic panels into their basic components: glass, aluminum frame, silicon cells, and smaller fractions like junction boxes and cables. The process starts with removing the aluminum frame, followed by shattering the glass to release the encapsulated solar cells and other materials. Subsequently, a series of mechanical crushing and sorting such as crusher, grinder, magnetic separator and air separator are used to separate different materials based on their size, weight, and magnetic properties.

Photovoltaic panel recycling machine

Photovoltaic panel recycling machine

The primary advantage of mechanical sorting is its relatively low energy consumption and simplicity, making it cost-effective compared to more complex methods such as pyrolysis. It also allows for high recovery rates of glass and metal components, which can be directly reused or sold as secondary raw materials. However, the technology struggles with extracting small amounts of silver from the silicon, and fails to deal with the plastic and adhesive residues thoroughly. This limitation necessitates supplementary processes for complete material recovery.

Chemical decomposition, or hydrometallurgical processing, uses chemicals to dissolve and separate the various materials within Photovoltaic panels, particularly silver, aluminum and copper. The process typically begins with a pretreatment step to fragment the panels further, followed by soaking them in chemical baths that selectively dissolve specific materials. Leaching agents, acids, or alkalis are commonly used, and the resulting solutions undergo several purification steps to isolate the desired metals.

Compared to mechanical sorting, chemical decompositio can increase the purity of recovered materials, particularly metals. However, this method requires careful handling of hazardous chemicals and generates wastewater that must be treated before disposal, adding operational complexity and cost. In addition, the energy consumption associated with multiple purification stages and chemical treatments can be significant.

Pyrolysis is a thermal decomposition process carried out in the absence of oxygen, where PV panels are heated to high temperatures, causing organic materials such as polymers and adhesives to decompose. The process result in the production of gas, liquid and solid residues, including recyclable materials (such as metals) and carbon-rich solid residues. Pyrolysis is particularly effective in processing plastic backsheets and encapsulation materials that are difficult to recycle by other means.

Pyrolysis machine

Pyrolysis machine

The biggest advantage of pyrolysis is its ability to process multiple materials at the same time, simplifying the recycling process of complex PV structures. It also reduces the volume of waste and can recover energy in the form of syngas or petroleum. However, the investment in pyrolysis machines is relatively large.

Determining the best technology for recycling photovoltaic panels depends on a variety of factors, including the composition of the panels, the scale of the recycling operation, economic considerations, and environmental friendliness. From an environmental protection perspective, mechanical sorting is better, but from a metal recovery perspective, chemical decomposition has a higher degree of purification. After research and development, the recovery rate of mechanical sorting photovoltaic panel recycling machine has reached 98%, which is no less than chemical decomposition. Therefore, more and more business owners in the market are choosing mechanical sorting.

Photovoltaic panel recycling machine

Photovoltaic panel recycling machine

Henan DOING, as a professional waste recycling machine manufacturer, has a team of highly qualified engineers and sales managers who can provide suitable solutions according to your requirements. If you are interested in getting involved in PV panel recycling business and purchase photovoltaic panel recycling machine, please feel free to contact us.