WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Australia is a solar energy powerhouse: over 3 million homes rely on rooftop solar photovoltaic panels, and large-scale solar farms drive its renewable goals. But as the first generation of panels nears the end of their 25-30 year lifespan, a critical question arises: Is solar panel recycling in Australia a crisis or an opportunity? The line between the two depends entirely on how we handle the coming wave of solar waste.

Let’s start with the “crisis” side. End-of-life solar panels contain lead and cadmium—toxic materials that leach into soil and groundwater if dumped in landfills. This threatens Australia’s fragile ecosystems, from rural farmlands to coastal waterways.

By 2035, annual solar panel waste here is projected to exceed 100,000 tonnes; without proper recycling, this waste becomes a pollution hazard and wastes valuable resources that could reduce reliance on imported raw materials.

However, challenges also present opportunities. Solar panel recycling in Australia is not yet fully established, representing a significant market gap. Appropriate processing technologies can extract reusable materials, reducing reliance on virgin resources and lowering the energy consumption required to produce new solar panels. For businesses and investors, participating in PV panel recycling can both support sustainable development and explore new market opportunities.

Products from recycling solar PV panels

Products from recycling solar PV panels

So here’s the “opportunity”: those panels aren’t just waste—they’re a hidden resource. Inside every end-of-life PV panel are high-value materials: durable aluminum frames, reusable glass, silicon (the core of solar cells), and copper wiring. Recycling these materials cuts the cost of manufacturing new solar panels, slashes carbon emissions from virgin mining, and creates a steady revenue stream for businesses. This is where DOING’s PV panel recycling machines step in—to turn the “crisis” into a profitable opportunity.

To achieve this goal, efficient recycling equipment and viable solar panel recycling solutions are essential:

DOING's solar panel recycling machine perfectly meets Australia's needs. It adopts physical crushing and sorting method, which is environmentally friendly and pollution-free.

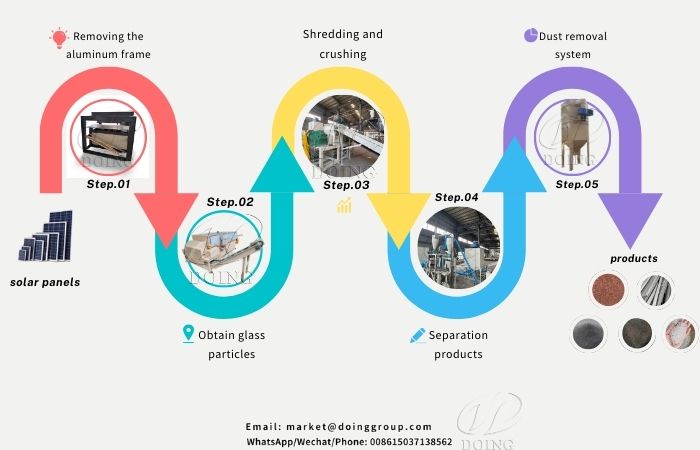

①Our multi-stage solar panel recycling process (automated frame dismantling, crushing, sorting) delivers results you can trust: over 99% recovery for aluminum frames, and over 95% for glass, silicon, and copper. The recycled materials boast 98% purity for aluminum, glass, and plastics—pure enough to re-enter local manufacturing supply chains.

Solar panel dismantling, crushing and sorting recycling process

Solar panel dismantling, crushing and sorting recycling process

②We prioritize efficiency: with PLC intelligent control, only 1-2 workers handle initial setup (our fully automated solar panel recycling machine need no manual intervention), reducing labor costs.

③For compliance, our fully enclosed systems use physical recycling (no chemical pollution) paired with pulse dust collectors, keeping dust in check and noise below 85 decibels—meeting Australia’s strict environmental regulations.

④We offer flexible support: standard capacities (500 kg/h and 1000 kg/h) or custom solutions to match your operation size, plus end-to-end help from consultation and plant design to installation.

Solar panel recycling in Australia isn’t a crisis—it’s a chance to build a sustainable, profitable business. With DOING’s proven solar panel recycling machine, you can turn solar waste into value. Ready to seize this opportunity? Contact DOING today for customized solutions tailored to Australia’s market.