WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

The international transition to electric vehicles and renewable energy is accelerating, leading to a massive generation of end-of-life lithium-ion batteries. Properly managing this stream is now a global priority, creating a pivotal shift from viewing these batteries as waste to recognizing them as a valuable resource. This paradigm is captured in the concept of "From Waste to Wealth," which lies at the heart of modern profitable lithium battery recycling projects. For entrepreneurs and investors, this trend opens a highly profitable opportunity, driven by strong market forces and supportive government policies that make lithium battery recycling a strategically advantageous venture.

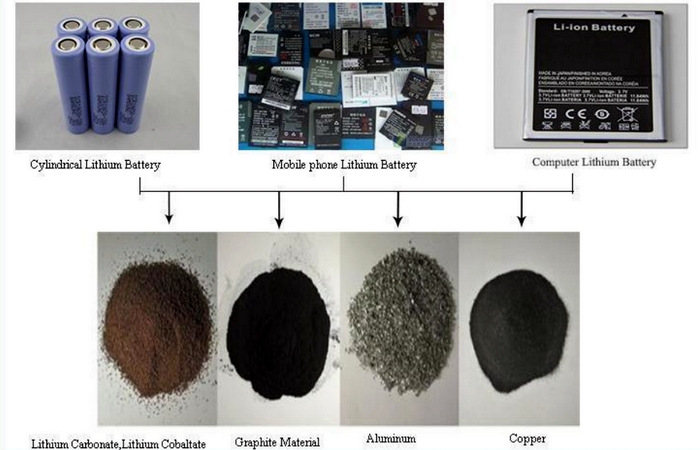

Metals extracted from used lithium batteries

Metals extracted from used lithium batteries

The robust profitability of the lithium-ion battery recycling industry is anchored in a uniquely favorable economic structure, characterized by manageable feedstock costs and high-value output. On the input side, the primary raw material—spent batteries—often carries low or even negative acquisition costs; in jurisdictions with strong Extended Producer Responsibility (EPR) frameworks such as the European Union, China, and several U.S. states, recyclers frequently receive collection fees, effectively creating a revenue stream at the inception of the process. This cost advantage is compounded by the value of the recovered materials: the process yields saleable copper and aluminum, but more critically, a valuable "black mass" rich in lithium, cobalt, and nickel. Given sustained demand from electric vehicle and energy storage markets, these critical minerals can command prices at 80-95% of their virgin material equivalents. This powerful combination of subsidized input costs and premium-priced outputs typically translates into pre-tax profit margins ranging from 15% to 40%, solidifying recycling as a financially sustainable and strategically vital link in the battery value chain.

While favorable market conditions establish the potential for profit, the actual profitability is determined by operational efficiency. The recovery rate of the lithium battery recycling equipment becomes the critical factor. Even a small percentage of material loss represents direct revenue forfeited. Therefore, technology capable of consistently achieving high recovery rate lithium recycling of 99% or higher is essential to minimize waste and maximize the economic value extracted from every ton of processed batteries. This high efficiency is what transforms market potential into tangible financial success.

DOING's lithium battery recycling equipment

DOING's lithium battery recycling equipment

DOING's lithium battery recycling equipment employs an innovative dry physical separation technology. Through a series of precise processes including crushing, grinding, magnetic separation, screening, and air separation, it effectively recovers valuable materials such as copper, aluminum, and black mass from spent lithium batteries. The entire process requires no chemicals or water, ensuring operational safety while preventing secondary pollution.

The equipment's outstanding advantage is its remarkable high recovery rate lithium recycling efficiency, consistently achieving a recovery rate of ≥99%. With an optimized screening system and precise air separation device, it maximizes the recovery of valuable materials, significantly enhancing profitable lithium battery recycling projects economic returns. Furthermore, the equipment is equipped with comprehensive environmental protection devices, including dust removal systems and exhaust gas treatment units, ensuring full compliance with environmental standards.

This combination of high recovery rate lithium recycling efficiency and environmentally conscious design represents more than just technical specifications - it forms the core of a sustainable value creation model. By ensuring maximum material yield while maintaining strict environmental standards, DOING's lithium battery recycling equipment provides investors with a dual advantage: superior economic returns coupled with compliance assurance. The technology effectively bridges the gap between profitability and sustainability, creating profitable lithium battery recycling projects that is not only financially rewarding but also environmentally responsible. This integrated approach positions our clients for long-term success in an increasingly regulated global market.

DOING waste lithium batteries recycling machine

DOING waste lithium batteries recycling machine

Based on extensive application experience across global markets, DOING's lithium battery recycling equipment delivers exceptional stability and adaptability tailored to regional requirements. We go beyond supplying advanced equipment by providing comprehensive technical support and lifelong after-sales services, ensuring customers achieve maximum operational efficiency and investment returns. DOING Company leverages over 14 years of expertise to develop customized, economically viable solutions for clients in key battery recycling markets including South Korea, Germany, Japan, Canada, and Australia. Our global support network, with service branches in strategic regions such as Nigeria, guarantees timely local assistance for installation, personnel training, and maintenance. This commitment to long-term partnership effectively minimizes operational risks and ensures sustained profitability for your recycling business.

Ready to build your profitable lithium battery recycling projects? Contact DOING today for a detailed project consultation and a tailored solution to maximize your returns.