WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

In today's global barbecue market, coconut shell charcoal is increasingly becoming the ideal choice for barbecue enthusiasts due to its long burning time, high heat output, and smokeless and odorless properties. For investors and manufacturers, transforming discarded coconut shells into high-value BBQ charcoal not only solves the problem of agricultural waste disposal but also presents a promising business opportunity.

Coconut shell charcoal production for BBQ

Coconut shell charcoal production for BBQ

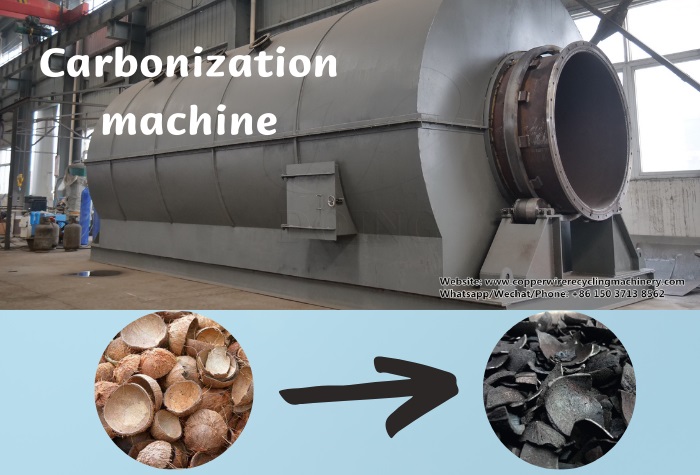

Compared to other biomass raw materials, coconut shells have a higher carbon content and density. Coconut shell charcoal processed with professional carbonization machine has low ash content and a burning time that is typically 2-3 times longer than ordinary charcoal. This characteristic makes it highly competitive in the high-end BBQ market. So, how is high-quality coconut shell charcoal produced through an industrial process? This article will provide a detailed breakdown of this process.

Freshly collected coconut shells usually have high moisture content and are bulky. First, the coconut shells need to be crushed into small, uniformly sized particles (usually around 3-5mm) using a crusher. If the raw material moisture content exceeds 15%, it also needs to be dried using an airflow dryer or rotary dryer to ensure suitable dryness, which is fundamental to guaranteeing the quality of subsequent carbonization.

This is the core step in converting coconut shells into charcoal. The coconut shell particles are pyrolyzed under high-temperature, oxygen-deficient conditions using a continuous carbonization furnace. The ideal carbonization temperature is typically 600-700°C, which removes moisture and volatile components from the raw material, leaving behind a high-carbon solid substance – coconut shell charcoal.

Coconut shell charcoal production carbonization furnace

Coconut shell charcoal production carbonization furnace

Environmental Note: Henan Doing Company's modern coconut shell carbonization furnace can collect and recycle the combustible gases produced during the carbonization process, thus reducing fuel costs. It is also equipped with a flue gas purification system to capture and treat the combustion gases or waste gases, ensuring that emissions meet standards and comply with environmental production requirements.

The product directly after carbonization is coconut shell charcoal powder, which lacks cohesiveness and cannot be directly shaped. At this point, the charcoal powder needs to be thoroughly mixed with an appropriate amount of binder (such as starch or a special chemical binder) and water in a roller mill mixer. This step not only increases the plasticity of the material but also further increases the density of the coconut shell charcoal powder through rolling.

This is a crucial step that determines the appearance and hardness of the barbecue coconut shell charcoal. The mixed material is fed into the coconut shell charcoal briquetting machine (also known as the briquetting press or extruder). Under strong mechanical pressure, the loose charcoal powder is compressed into various shapes, such as rods, spheres, or blocks.

Charcoal briquetting press or extruder machine

Charcoal briquetting press or extruder machine

In addition to providing professional biomass carbonization machine, Henan Doing Company also provides high-performance charcoal briquetting press machine. The charcoal briquetting machine uses strong pressure to produce charcoal blocks with higher density, longer burning time, less breakage, and easier transportation.

The newly pressed charcoal briquettes contain a certain amount of moisture and need to be dehydrated using the drying machine. After the dried coconut shell charcoal has completely cooled, it can be weighed and packaged, ready for market.

Although traditional charcoal production methods using earthen kilns still exist, mechanized production of charcoal briquettes has become the mainstream trend in the industry due to its efficiency, yield, and environmental compliance. Producing high-quality coconut shell charcoal for BBQ requires scientific production processes and reliable charcoal making machine.

Henan Doing Company, as a professional manufacturer of charcoal manufacturing machine, is committed to providing customers with a one-stop solution from coconut shell raw material processing to finished barbecue charcoal packaging. If you are looking for an efficient coconut shell charcoal production line solution, or have any questions about specific equipment parameters, please feel free to contact our technical team.