WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

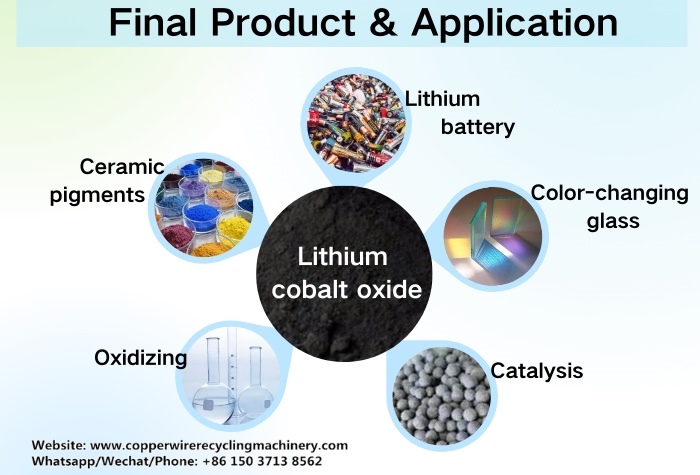

Recycling the components of lithium ion batteries is Unlocking the Treasure Trove. Lithium-ion batteries contain a variety of recyclable precious metal components, such as lithium, cobalt, nickel, aluminum, etc. These components can not only reduce resource consumption through recycling and reuse, but also greatly reduce the pollution of scrap lithium batteries to the environment.

The positive electrode materials of lithium-ion batteries contain a variety of recyclable components, mainly including cobalt, nickel, lithium (the core component of lithium batteries), and manganese. These materials account for a large proportion of the battery and have high value. They can be recycled to make new batteries or other industrial products.

Lithium ion battery recycling components and uses

Lithium ion battery recycling components and uses

The main component of the negative electrode material of lithium ion batteries is graphite. The recycling of graphite powder can be extracted by mechanical and chemical methods, and after processing, it can be put back into use as the negative electrode material of new batteries, and can also be used as industrial lubricants. The recycling and reuse of graphite is of great significance to the battery manufacturing industry, especially in improving the energy density of batteries and extending the battery life.

Copper foil is used for the negative electrode current collector of lithium-ion batteries, and aluminum foil is mainly used for the positive electrode current collector of lithium batteries. The copper and aluminum in waste lithium batteries can generally be separated by physical means. Copper can be reused in industrial products such as wires and cables, while aluminum can be recycled and reprocessed to make new battery shells or for other industrial purposes.

Recycling lithium-ion battery components: copper and aluminum

Recycling lithium-ion battery components: copper and aluminum

Other components in lithium ion batteries, such as battery shells and plastic separators, can also be recycled. Battery shells are usually made of metal or plastic materials. Through mechanical crushing and separation, the aluminum, steel and plastic in them can be extracted for reuse. Plastic separators are used to separate the positive and negative electrodes inside the battery, and can also be reused in low-end separators or plastic products through mechanical separation.

In short, by recycling the different components of lithium-ion batteries, it can not only reduce pollution to the environment, but also reduce resource waste, effectively reduce production costs, and promote the development of a circular economy.

Professional lithium ion battery recycling plant

Professional lithium ion battery recycling plant

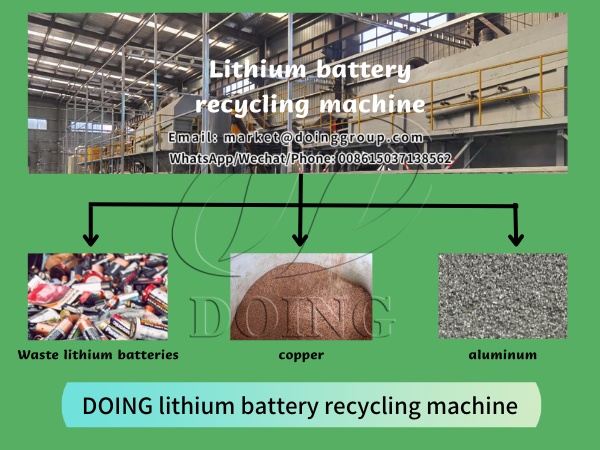

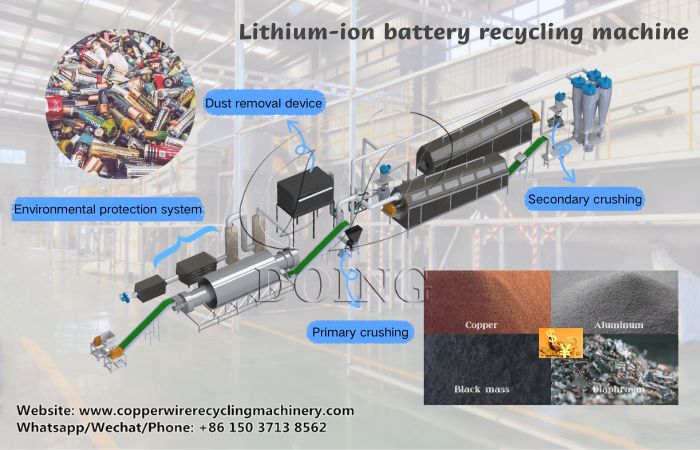

To achieve efficient recycling of lithium ion battery components, professional recycling and processing equipment is indispensable. DOING lithium ion battery recycling plant adopts a physical and mechanical crushing process route, which can efficiently recycle these valuable components. Specifically, our lithium-ion battery recycling process includes discharge, disassembly, crushing, sorting and other steps.

1. Efficient crushing and sorting system: Through multi-stage crushing and sorting processes, different materials, such as copper, aluminum and graphite powder, are separated by the particle size differences of different components of lithium ion batteries. In the end, a recovery rate of more than 98% can be achieved, and the recycled materials have a high purity and can be directly used to produce new lithium-ion batteries or other industrial uses.

Multi-stage crushing and sorting system for efficient recycling of lithium ion batteries

Multi-stage crushing and sorting system for efficient recycling of lithium ion batteries

2. Automated operating system: The entire lithium battery recycling system is equipped with a PLC intelligent control system, which is easy to operate and maintain, and reduces manual operation links. Through the intelligent system, key parameters are monitored in real time to ensure that the entire process runs stably and the components in the recycling process are maximized.

3. Environmental protection treatment system: DOING lithium ion battery recycling plant is designed with full consideration of safety and environmental protection. The whole recycling process adopts fully enclosed treatment, and is equipped with exhaust gas treatment devices to effectively control dust and harmful gases. Ensure that no secondary pollution will be generated during the recycling process, and the entire recycling process meets environmental protection requirements.

Environmentally friendly lithium-ion battery processing system

Environmentally friendly lithium-ion battery processing system

4. Customizable configuration: We provide lithium ion battery recycling plants with different processing capacities, such as 500kg/h, 1000kg/h and 2000kg/h, and can also be customized according to different processing needs of customers. Whether in large-scale industrial production or small and medium-sized lithium battery recycling stations, our equipment can meet recycling tasks of different scales and needs.

The recycling and reuse of lithium ion battery components is not only feasible, but also an inevitable choice for future sustainable development. Our lithium ion battery recycling plant can provide customers with an environmentally friendly and economical solution. If you have any questions or needs about lithium-ion battery recycling, please feel free to contact us, and we will provide you with professional advice and services.