WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Copper cable wire recycling business is really popular now. So after people buy the copper cable wire recycling machine for this business, they may care more about the maintenance for this machine. When it comes to maintaining a copper cable wire recycling machine, there are several key requirements to keep in mind. Here are some important maintenance requirements to ensure your copper cable wire recycling machine remains efficient and reliable.

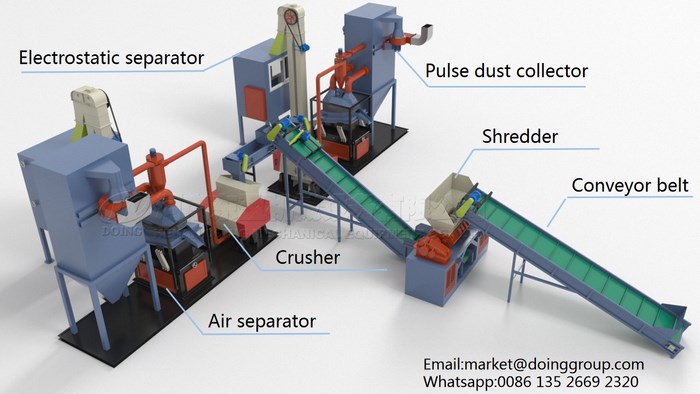

Copper cable wire recycling machine

Copper cable wire recycling machine

When machine running, the bearings need to be smoothly. So please take care that, the bearings need to be added of the grease often, about every 1-2days. One of the most important maintenance requirements for a copper cable wire recycling machine is lubrication. The machine has many moving parts that require lubrication to reduce friction and prevent wear and tear. It is essential to lubricate the machine regularly to ensure it operates smoothly and efficiently. The lubrication schedule will depend on the manufacturer’s recommendations, but it is usually recommended to lubricate the machine every six months. For the reducer on the machine, it needs to be added of gear oil too. Normally we’ll check the oil level through the indicating pipe onside the reducer, if the oil lever lower than the red mark, then add oil. So in daily life running, these details need to be concentrated on too.

Some parts of the copper cable wire recycling machine may need to be replaced over time. An example is the crusher blade in the copper cable wire recycling machine. Crusher will crush the copper cable wires directly with the blade. So for long time use, the blade will be obtuse, then you will need to sharpen it so that it can ensure the crushing efficiency. After sharping many times, then the blades will need to change. And actually for different suppliers, they will equip with different materials of the blade with the crusher. That will affect the replacement period too. It is essential to replace these parts promptly to ensure the machine operates efficiently. The replacement schedule will depend on the manufacturer’s recommendations, but it is usually recommended to replace parts every year. The crusher of DOING copper cable wire recycling machine use 65Mn alloy blades, which has good toughness and high wear resistance guarantee.

Crusher

Crusher

Regular inspection is also essential to ensure the copper cable wire recycling machine operates efficiently. The machine has many parts that can wear out over time, and it is essential to inspect them regularly to identify any issues and address them promptly. The inspection schedule will depend on the manufacturer’s recommendations, but it is usually recommended to inspect the machine every six months. If you feel any unusual during the machine running, the first thing we should do is to stop the machine, then check, or contact with the supplier of the questions.

Another important maintenance requirement for a copper cable wire recycling machine is cleaning. The machine can accumulate dust, dirt, and other debris over time, which can affect its performance. It is essential to clean the machine regularly to remove any debris and ensure it operates efficiently. The cleaning schedule will depend on the manufacturer’s recommendations, but it is usually recommended to clean the machine every three months.

So hope above will provide some help for the people who have been in the copper cable wire recycling business. Regular maintenance is essential to ensure a copper cable wire recycling machine operates efficiently and effectively. By following these maintenance requirements, you can ensure that your copper cable wire recycling machine operates efficiently and effectively, reducing waste and saving money.

Project

Project

And to be honest, for the beginning of supplier choosing, that’s very important too. That will affect the after-sales service and the later maintenance requirements support. A reliable supplier can provide support and ways in time, to help you solve the questions during running. For our DOING Company, we have been in the copper cable wire recycling machine manufacturing area for more than 12 years, and have exported machines to over 90 countries. So welcome you to consult of our copper cable wire recycling machines and visit our company too!