WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

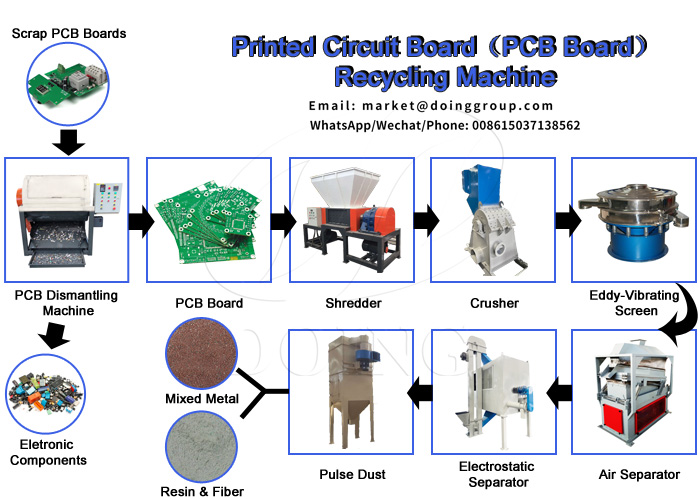

There are many metals, like copper, silver, tin, palladium, chrome, etc. inside waste circuit boards. PCB recycling machine is used to separate these precious metals from the waste circuit boards. Well, how does PCB recycling machine works?

To gain a comprehensive understanding of the working process of PCB recycling machine, let us delve into its intricate working process, as elucidated by a demonstrative video.

The initial stage of the working process uses a double-shaft shredder. Shredder is tasked with reducing large or thick waste circuit boards into small fragments.

Following the shredding phase, a hammerhead crusher and hammer crusher will be used to process the small fragments, to crush them into smaller particles. The hammer crusher is made of wear-resistant and highly durable 65Mn steel, which can effective crush waste circuit boards fragments.

The crushed materials will enter an eddy-vibrating screen, which is used be to control the particle size. Fitted with a 26mesh screen, eddy-vibrating screen can prevent the oversized particles from entering the next step. The bigger particles will be returned to the hammer crusher for further processing until they successfully meet the required particle size criteria.

Working process of PCB recycling machine

Working process of PCB recycling machine

Subsequently, an air separator takes center stage in the process, exploiting the distinct gravity of metals and resin fibers. Through this advanced technique, crude metals are effectively segregated from the resinous component, achieving an impressive separation rate of approximately 98%.

Since some materials are completely broken, the gravity of some metals may be similar to that of resin fibers, and air separation cannot separate them clearly. Therefore, electrostatic separator is used to separate metals in resin fibers, according to their different conductivity. The separation rate can reach to 99%.

Electronic components dismantling machine

Electronic components dismantling machine

In pursuit of even higher metal purity, an electronic components dismantling machine can be used to remove the electronic components. Harnessing the unique property of metal tin, which melts at elevated temperatures, along with the frictional forces exerted on the circuit boards, this auxiliary equipment efficiently removes electronic components from the waste stream prior to the main recycling process.

Throughout the entire recycling operation, a cyclone and a pulse dust collector can collect the dust with the efficiency of 99.5%, ensuring a clean and safe working environment.

PCB recycling machine

PCB recycling machine

Established in 2011, Doing Group has a wealth of 13 years' manufacturing experience to the PCB recycling industry. For those interested in acquiring state-of-the-art PCB recycling machine, look no further than Doing Group. Trust us to provide you with top-quality machinery and an exceptional service experience tailored to your specific requirements.