WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

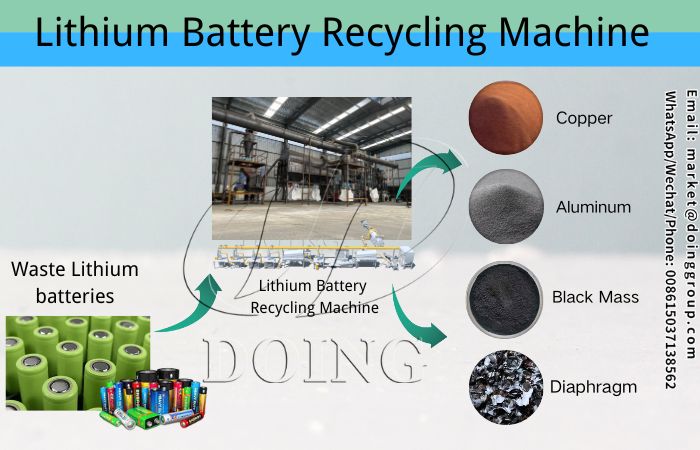

The recycling of waste lithium batteries is a field of great economic value, because lithium batteries contain rare earth elements and non-ferrous metals with high economic value, such as cobalt, lithium, nickel, copper, aluminum, etc. By recycling waste lithium batteries, these metals can be extracted and reused to create huge economic profits.

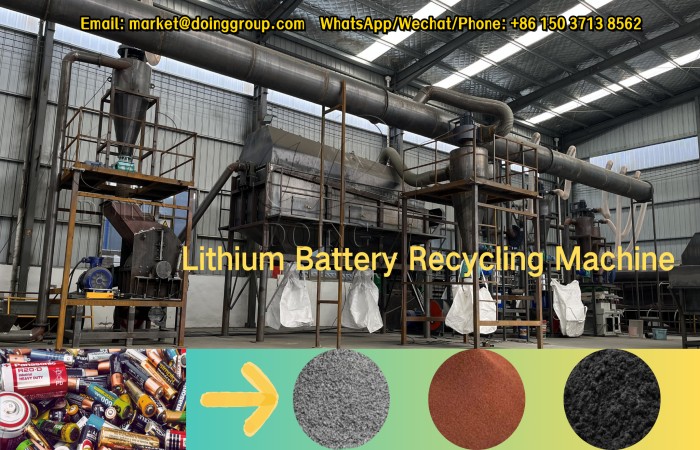

Lithium battery recycling machine

Lithium battery recycling machine

Methods for recycling waste lithium batteries

The recycling methods of lithium batteries mainly include physical recycling, chemical recycling and biological recycling.

1. Physical recycling method:

Separation by physical means such as mechanical crushing, screening, magnetic separation, gravity separation, etc., the operation is simple, and the recovery rate of metal and black powder is high.

2. Chemical recycling method:

The metal elements and organic matter in waste lithium batteries are separated by chemical reactions, but the operation process is complicated and will cause pollution to the environment.

3. Biological recovery method:

It is still in the research stage and the recovery efficiency is low.

Lithium battery recycling machine

Lithium battery recycling machine

Working process of waste lithium battery recycling machine

Among the above waste lithium battery recycling methods, mechanical physical recycling methods are the most popular among investors. The working process of lithium battery recycling machine is as follows:

Step 1: Soak the waste lithium battery in salt water to short-circuit the positive and negative poles of the battery, thereby releasing excess battery energy.

Step 2: Send the discharged lithium battery to the shredder and crusher to process it into small particles.

Step 3: Carbonization. Organic matter is converted into carbon-like substances by heating the battery residue in a low-oxygen environment. This process can remove the diaphragm of the lithium battery. If you need to collect the diaphragm of the lithium battery, DOING can also equip the linear screen to select the diaphragm of the lithium battery according to your needs.

Step 4: Use the drum screen to select the black powder. Most manufacturers on the market are equipped with linear screens, which not only have a small output, but also have unclean screening. DOING is equipped with a drum screen with a sorting rate of up to 80%.

Step 5: The fragments of the lithium battery after crushing enter the magnetic separator, and the magnetic attraction is used to separate the iron. After the remaining material is turned into powder by the mill, it enters the separation equipment such as the circular vibration screen, the airflow specific gravity separator, etc., which uses the difference in material size and weight to efficiently separate copper, aluminum and black substances.

High-profit lithium battery recycling strategy

Based on many years of project guidance and equipment installation experience, we have summarized the following tips for developinglithium battery recycling business and make high profits.

1. Scaled operation:

In the waste lithium battery recycling industry, scaled operation is one of the key strategies to improve profit margins. With the continuous expansion of the recycling scale, enterprises can achieve effective lithium battery recycling cost reduction and significant improvement in benefits in a variety of ways.

2. Industry chain integration:

In the waste lithium battery recycling industry, industry chain integration has become a key strategy to improve profit margins. By establishing close cooperation with upstream and downstream enterprises, recycling companies can maximize their profits.

For example: Establish strategic cooperation with battery manufacturers and automobile manufacturers to obtain a stable supply of waste lithium batteries.

3. Use efficient lithium battery recycling machine:

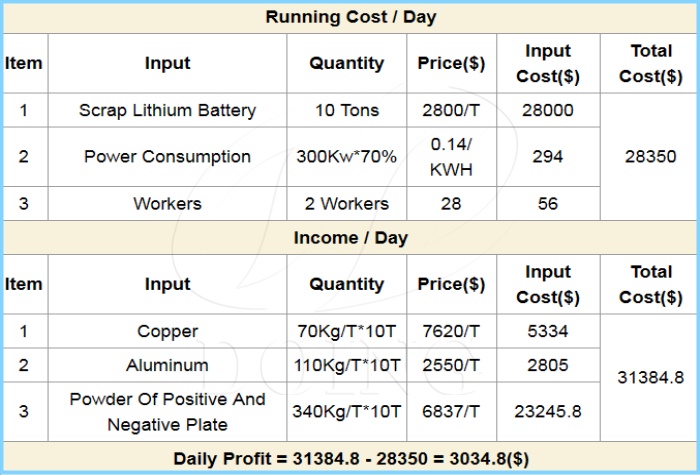

DOING lithium battery recycling machine adopts dry mechanical crushing and physical sorting technology to efficiently recycle valuable parts of lithium batteries, such as black powder, diaphragm, copper and aluminum. The separated copper and aluminum can be sold directly to the metal trading market for profit. The following is a profit analysis table for lithium battery recycling business for your reference to calculate the actual profit.

Lithium battery recycling profit

Lithium battery recycling profit

If you are interested in lithium battery recycling machine, please feel free to contact us. DOING can provide customers with a range of services such as suitable machines, documentation, technical support, installation and after-sales service.