WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Waste aluminum and plastic separator machine is a machine for separating and recycling aluminium and plastic from scrap aluminium-plastic composites.

The input materials

The input materials

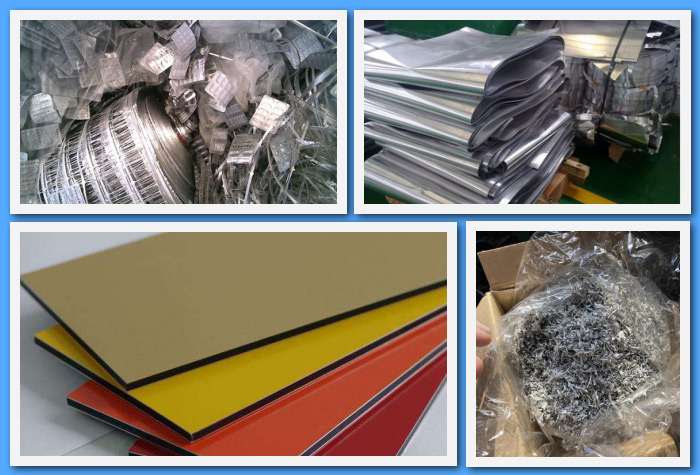

Waste aluminum and plastic separator machine can process a wide range of aluminium-plastic composites in life. Specifically, the raw materials that can be handled are aluminum-plastic foil, aluminum-plastic panel, medical blister packs, aluminium-plastic shavings and so on. The market for raw materials is extensive. According to statistics, there are thousands of enterprises producing and using aluminium foil, of which pharmaceutical plants alone have tens of thousands of tonnes of aluminium sheet trimmings every year.

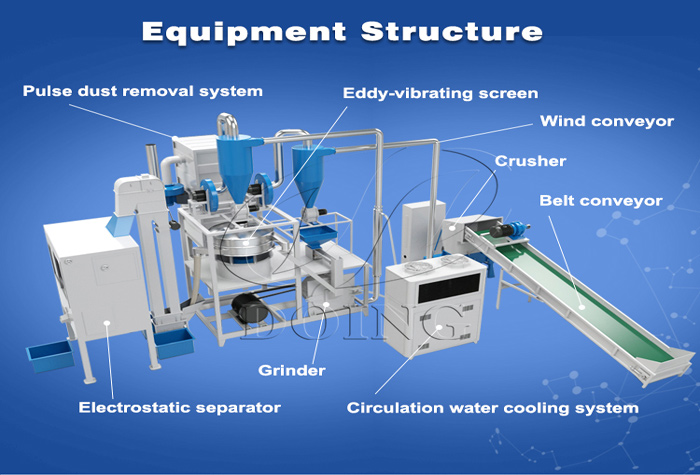

1.Crushing: Crushing of aluminium-plastic composites into small 1mm particles with crusher.

2.Grinding: Grinding these small 1mm particles into 24 mesh powder with grinding mill.

3.Screening: An eddy-vibrating screen is used to control the size of the powder and larger powders are sent back to the mill for further grinding.

4.Separating: Electrostatic separator is used to separate out 99% of the metals and non-metals depending on different charge levels of the the metals and non-metals.

Final products and application

Final products and application

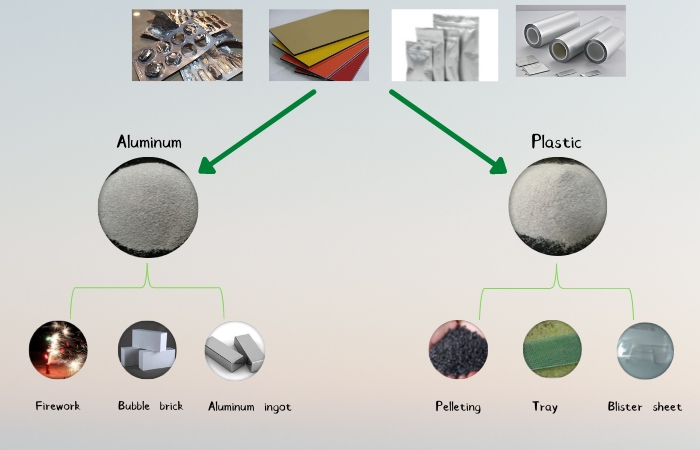

With the above workflow, you can get aluminum and plastic powders from the waste aluminum and plastic separator machine. Aluminum powders can be used directly to sell for money. Meanwhile, aluminium powder can also be used to make aluminium ingots, aerated bricks and fireworks. Plastic powder can be used to make blister sheets, seedling trays and pelletizing.

3D equipment structure

3D equipment structure

1.The crusher uses SKD-11 alloy blades with hardness in HRC58, which could ensure the good toughness under high wear resistance guarantee with the alternated splayed structure.

2.Eddy-vibrating screen is a high-precision screening machine with low noise, high efficiency and whole sealing structure.

3.Grinding mill is equipped with air cooling and water cooling system, which could avoid the material melting cause by high temperature generated from grinding process.

4.Electrostatic separator can separate metal and plastic by high voltage electrostatic, high separate rate over 99.9%.

5.Pulse dust collector, equip with pulse valve to clean dust automatically, has high dust remove rate over 99.5%

6.Use water cooling and wind cooling system, high grinding efficiency and recovery rate.

If you are interested in this waste aluminum and plastic separator machine, please contact DOING. DOING provides one-stop service and has a perfect after-sales service team.