WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

DOING PVC blister packs scrap recycling machine

DOING PVC blister packs scrap recycling machine

DOING PVC blister packs scrap recycling machine adopts crushing, grinding, separating, dust removing technology process to achieve aluminum and plastic separated automatically and completely, high efficiency, and only needs 1-2 persons to operate.

1. Crushing: Input waste aluminum plastic composite materials into crusher, the waste aluminum plastic composite materials will be crushed into small particles.

2. Grinding: Grinding the particles into powder by using a grinder.

3. Screen: Use an eddy-vibrating screen to control the size of powder.

4. Separating: Use an electrostatic separator to separate aluminum and plastic.

5. Dust collecting: During whole process, we collect the dust by using a pulse dust collector.

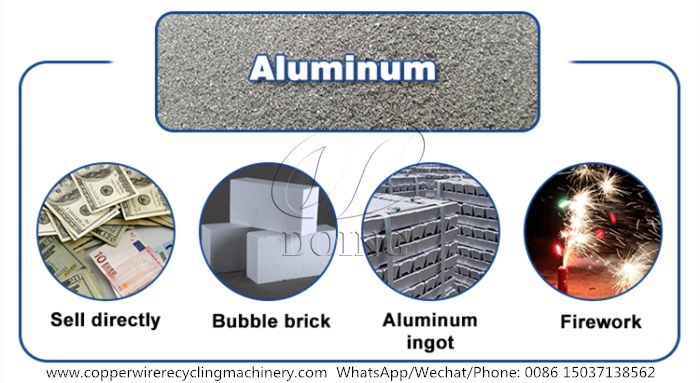

The recycled aluminum powder could be sold in metal trading market directly, or used for fireworks or other aluminum products making later. The selling price normally ranges from USD1500 to USD2300 per ton, which may be different in different local markets.

The usage of recycled aluminum powder

The usage of recycled aluminum powder

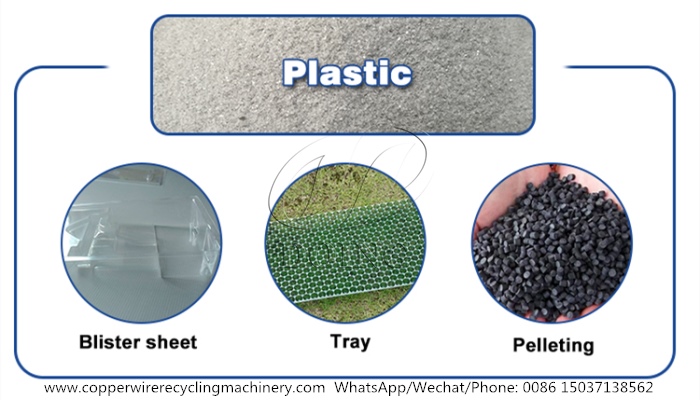

The PVC powder could be used for plastic granules to make new plastic products. Its selling price ranges from hundreds dollars to thousands dollars per ton, depending on the plastic types and quality.

The usage of recycled PVC powder

The usage of recycled PVC powder

The selling price of aluminium on the market is now around $2,450 per ton. And different plastics have different prices, the selling price of PE is about $500 per ton, and the price of PVC is about $350 per ton.

In order to let you have a more intuitive understanding of the aluminum plastic recycling business, Doing Company has made the following profit analysis table for your reference by taking the waste aluminum plastic PVC blister packs scrap as an example:

Running cost / Day | |||||

Item | Input | Quantity | Price($) | Input cost($) | Total cost($) |

1 | Waste aluminum plastic composite materials | 300kg/h*8h=2.4T | 190 | 456 | 551.43 |

2 | Power consumption | 46Kw/H*8H=368KwH | 0.14/KwH | 52.57 | |

3 | Workers | 2 workers | 21.42/Day | 42.86 | |

Income / Day | |||||

Item | Output | Quantity | Price($) | Income($) | Total income($) |

1 | Aluminum | 2.4T*20%=0.48T | 2450 | 1176 | 1848 |

2 | Plastic | 2.4T*80%=1.92T | 350 | 672 | |

Daily profit = daily income - daily cost=1848-551.43=1296.57($) | |||||

(Note: The above data is based on market conditions and customer feedback.)

Thus it will be seen the profit of PVC blister packs scrap recycling using PVC blister packs scrap recycling machine is very generous. Because after DOING PVC blister packs scrap recycling machine processing, the separation rate of PVC and aluminum could be above 99%, very pure, the PVC and aluminum will have better selling market price.

1. The crusher use SKD-11 alloy blades with hardness in HRC58 which could ensure the good toughness under high wear resistance guarantee with the alternated splayed structure.

2. Grinding mill is equipped with air cooling and water cooling system, which could avoid the material melting cause by high temperature generated from grinding process.

3. Electrostatic separator can separate metal and plastic by high voltage electrostatic, along with bucket elevator to form an automatic sorting circle system to get high separate rate over 99.9%

4. Pulse dust collector, equip with pulse valve to clean dust automatically, has high dust remove rate over 99.5%

1. Q: How is the separation rate? How is the purity of products?

A: The separation rate of aluminum and plastic can be reach more than 99%. (Tips: You can test the aluminum purity through burning it.)

2. Q: Can I visit your factory?

A: Very welcome you to visit DOING factory. If you can't came because of something, we can provide online tour service of DOING factory to see PVC blister packs scrap recycling machine.

DOING factory welcome you visit

DOING factory welcome you visit

3. Q: How can I make sure the effect of the equipment?

A: We have prototype equipment in factory, so you can watch the equipment test running effect. And before delivery, we must test the machine, after which is qualified, it can be sent to customer.

4. Q: How is your PVC blister packs scrap recycling machine installed?

A: We can arrange our engineer to guide the installation at the scene or online. Besides, we also attach installation labels to each accessory of the equipment, so that customer can independently complete the installation process.

If you are going to start the business to extract of aluminum and plastic from PVC blister packs scrap, welcome to contact us for more technology support or information about DOING PVC blister packs scrap recycling machine.