WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

With the gradual expansion of solar energy applications, the use of solar panels has steadily increased. Photovoltaic panels gradually age over time. Therefore, understanding the lifespan of solar panels, recycling processes, and the selection of related machine is of practical significance to industry participants.

Solar panels are typically designed to last between 20 and 30 years. With age, the power generation efficiency of PV modules decreases, requiring replacement when efficiency drops below a certain level. If these retired solar panels are not properly handled, they may have a certain impact on the environment. Professional solar panel recycling not only reduces resource consumption but also promotes recycling and sustainable development.

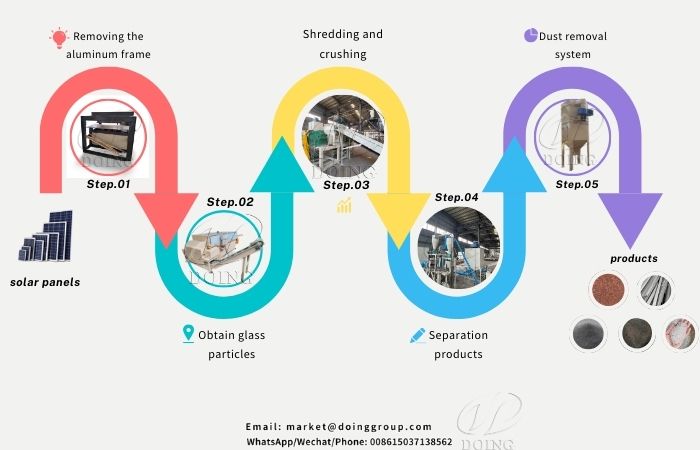

The solar panel recycling process involves the processing and separation of different materials. Typically, the solar panel recycling process includes several steps:

Solar panel dismantling, crushing, sorting and recycling process

Solar panel dismantling, crushing, sorting and recycling process

1. Disassembly and Preliminary Sorting: The panel's external aluminum frame and glass can typically be mechanically removed to separate the recyclable materials: aluminum and glass.

2. Material Extraction: Solar panels contain many valuable materials, such as silicon, silver, aluminum, and copper. Recycling companies can use mechanical physical methods to extract these reusable materials from discarded photovoltaic panels.

3. Recovery and Reuse: The recovery of silicon and metals is a key step in the solar panel recycling process. These extracted materials can then be processed and used to manufacture new solar panels or for other industrial applications, reducing resource waste.

During the solar panel recycling process, appropriate recycling equipment can help improve processing efficiency and material recovery rates. Common solar panel recycling machine includes disassembly, crushing, and sorting equipment. These machines typically feature a degree of automation and can accommodate the processing needs of solar panels of varying sizes.

Solar panel dismantling, crushing and sorting machine

Solar panel dismantling, crushing and sorting machine

DOING specializes in the research and development and production of solar panel recycling machine, providing a range of efficient and environmentally friendly recycling equipment solutions. The entire recycling process emphasizes efficient resource utilization and minimizes environmental impact.

Efficient Material Separation System: This system efficiently separates valuable materials such as glass, aluminum frames, silicon (including silver), and copper from solar panels, achieving a recovery rate exceeding 95%.

Environmentally Friendly and Pollution-Free: Our solar panel recycling machine utilizes a fully enclosed system and is equipped with a dust removal device to effectively control dust emissions and ensure the recycling process is environmentally friendly.

Advantages of DOING solar panel recycling machine

Advantages of DOING solar panel recycling machine

Highly Automated: The entire solar panel recycling process utilizes PLC intelligent control, reducing manual operations, improving recycling efficiency, and lowering labor costs.

Highly Adaptable: This system accommodates solar panels of various sizes, enabling flexible response to market fluctuations.

Solar panel recycling is a highly beneficial endeavor. Understanding the lifespan of solar panels, recycling processes, and selecting the right solar panel recycling machine will contribute to the healthy development of the industry. If you are interested in photovoltaic panel recycling or would like to learn more about our equipment, please contact us via our website or by phone.