WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

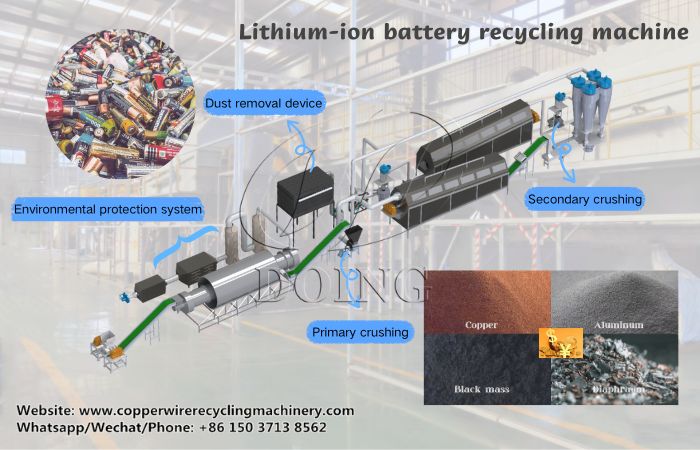

As lithium ion batteries power more EVs and consumer electronics, their recycling becomes critical for sustainability. However, the recycling process is not without challenges—safety risks, low efficiency, and strict regulatory demands often stand in the way of profitable and eco-friendly operations. These challenges can deter businesses unless paired with the right technology.

Safety is the first major challenge. Lithium ion batteries contain flammable electrolytes and reactive materials. Improper handling during shredding or crushing can trigger thermal runaway, leading to fires or explosions. Traditional manual processes heighten this risk and slow down operations.

Efficiency is another key issue. Material loss during lithium battery recycling is a common problem in the industry. Outdated Lithium ion battery recycling machine often delivers low material recovery rates (below 90%), wasting high-value metals like lithium, cobalt, and nickel. Manual labor also drives up operational costs, reducing profit margins for recyclers. Maintaining a high recovery rate for valuable metals while processing them efficiently places significant demands on process precision and equipment stability.

Recyclable precious metals in lithium-ion batteries

Recyclable precious metals in lithium-ion batteries

Compliance adds a third layer of difficulty. Global regulations—such as the EU’s Battery Directive—set strict standards for emission control, waste treatment, and material recovery. Failing to meet these rules results in heavy fines and business disruptions.

In terms of safety risk management, the equipment integrates multiple protection mechanisms, including premature discharge, temperature monitoring, and inert gas protection, helping to reduce safety hazards in key processes. Furthermore, the entire lithium-ion battery recycling process utilizes a PLC-controlled automated system, minimizing manual interaction and reducing safety risks.

To improve material recovery rates, our lithium-ion battery recycling machine focuses on process optimization in the crushing and sorting stages. This multi-stage crushing and sorting process achieves a material recovery rate exceeding 98%, extracting high-purity copper, aluminum, and black mass (containing lithium, cobalt, and nickel) to maximize resource value.

Lithium-ion battery multi-stage crushing and sorting recycling process

Lithium-ion battery multi-stage crushing and sorting recycling process

To meet international standards, our fully enclosed lithium battery recycling system was designed with environmental requirements in mind. It is equipped with advanced exhaust gas and dust treatment systems, helping users comply with relevant environmental standards and avoid pollution fines. We also offer flexible production capacities (500 kg/hour to 2,000 kg/hour) and customized solutions to meet your specific needs.

With DOING, lithium ion battery recycling challenges become opportunities for safe, profitable, and sustainable operations. Ready to overcome these hurdles and grow your battery recycling business? Leave a message today to get professional advice and tailored solutions from DOING.

Recommended Reading: [ What Types of Scrap Batteries Can the DOING Battery Recycling Machine Process? ]