WhatsApp

WhatsApp

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

As a clean and green energy, solar energy has become the lowest-cost source of electricity generation and the fastest-growing new source of electricity in the United States and many other parts of the world in recent years. With the rapid development of the solar energy industry, the application of solar panels has gradually increased. However, with the arrival of the service life, the recycling of solar panels has become more and more important. According to the International Renewable Energy Agency (IRENA), the global amount of photovoltaic panel waste to be recycled will reach 8 million tons by 2030 and may exceed 78 million tons by 2050.

1. Environmental protection needs: If the waste generated by solar panels during use is not properly handled, it will cause certain pollution to the environment. Through recycling, the impact of harmful substances on the ecological environment can be effectively reduced, resource waste can be reduced, and it is in line with the principle of sustainable development.

2. Resource reuse: The main materials of solar panels include silicon, glass, aluminum, etc., among which the resource reserves of silicon are limited. Recycling these materials can not only save raw materials, but also reduce the burden of mineral mining, realize resource reuse, and reduce production costs.

Solar panel raw materials and recycled products

Solar panel raw materials and recycled products

3. Extend the service life of equipment: Proper recycling can extend the service life of solar panel equipment and reduce the demand for new equipment, thereby further promoting the efficient use of energy.

4. Promotion of policies and regulations: With the continuous improvement of environmental protection policies in various countries, solar panel recycling has become a necessary task in the industry. More and more countries and regions have begun to introduce relevant regulations requiring the standardized recycling and treatment of discarded solar panels.

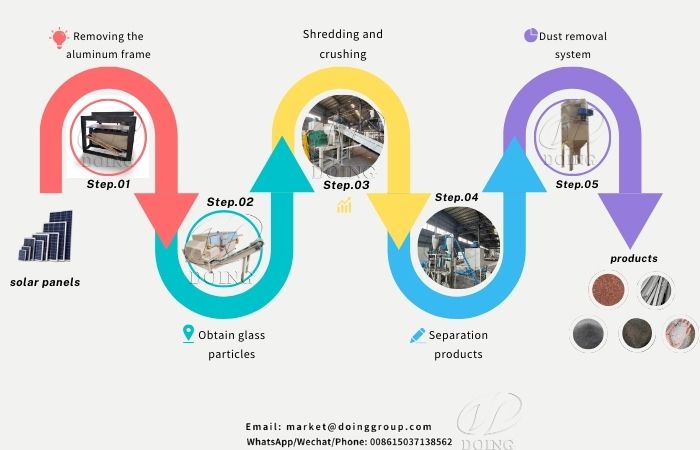

To recycle the most common solar panels (which use crystalline silicon to generate electricity), the DOING team has developed a complete solar panel recycling solution that includes the following steps: first, the junction box and aluminum frame are removed, then the EVA film is decomposed through heat treatment to separate the glass, then the panels are cut and crushed, the remaining debris is ground, and the crushed material is subjected to a multi-step proprietary process to separate the plastic and recover the precious metals such as silicon and copper.

DOING solar panel recycling machine process

DOING solar panel recycling machine process

The purity of the recycled product is critical, and each link requires the support of dedicated machine to ensure the quality and value of the recycled materials. The solar panel recycling machine provided by DOING uses advanced technology and processes to complete these steps in a cost-effective and environmentally friendly manner, thereby obtaining high-purity materials that can be used to manufacture new products and solar panels. The equipment also uses an automated control system that can monitor the recycling process in real time to ensure stable operation and safe production.

DOING professional solar panel recycling machine to recover photovoltaic panels

DOING professional solar panel recycling machine to recover photovoltaic panels

Investing in professional solar panel recycling machine not only meets environmental regulations, but also creates additional economic benefits. Our solar panel recycling solutions have been verified in multiple projects, with stable equipment operation and good recycling results. We can provide customized services according to the specific needs of our customers, providing full support from equipment selection to installation and commissioning. If you are considering solar panel recycling business or need to upgrade your existing recycling facilities, please feel free to contact us.