WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

In the energy processing sector, charcoal carbonization furnaces play a central role in efficiently converting various types of biomass raw materials into charcoal. However, the price of charcoal carbonization furnaces varies significantly, ranging from several thousand to hundreds of thousands of US dollars. So, what exactly is the price of a charcoal carbonization furnace, and what factors influence it? Below is a detailed analysis.

The carbonization process requires high-temperature conditions, and high-quality furnaces are typically constructed from heat-resistant and corrosion-resistant specialty alloys or stainless steel. It may be 20%-30% more expensive than equipment made of ordinary steel.

For instance, the DOING carbonization furnace made of 310S stainless steel or Q345R boiler plate which has advantages in durability and stability. These materials ensure stable operation under prolonged high-temperature conditions, extend the equipment’s lifespan, and reduce maintenance costs. Lower-priced alternatives often use standard steel, which is prone to oxidation and deformation, leading to higher long-term maintenance costs and lower overall value.

Doing carbonization furnace equipment

Doing carbonization furnace equipment

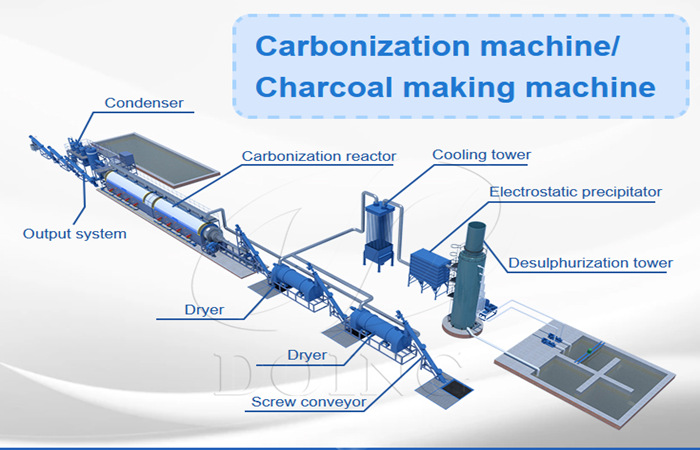

Charcoal carbonization furnaces equipped with advanced technology generally command higher prices. For example, units with intelligent temperature control systems ensure precise carbonization temperatures, resulting in consistently high-quality charcoal output. Furnaces with efficient environmental treatment systems can recycle and purify smoke and tar generated during carbonization, meeting international environmental emission standards and reducing compliance burdens for businesses. Additionally, highly automated and user-friendly models involve higher R&D and production costs, which are reflected in their selling prices. As a case in point, DOING’s carbonization furnaces integrate these advanced features—intelligent control, automated operation, and eco-friendly treatment—ensuring both high efficiency and environmental compliance, which justifies their value in the market.

The size and model of a charcoal carbonization furnace directly impact its price. Small-scale charcoal klins/charcoal retorts, with simpler structures and lower hourly processing capacities, are suitable for small production operations and typically cost between $5,000 and $20,000. In contrast, large-scale continuous carbonization furnaces offer high automation levels and robust processing capabilities, handling several tons or more of raw materials per hour. These industrial-grade systems can meet the demands of large-scale production and are priced from $50,000 to over $200,000. Businesses should select a model based on their production scale and budget, keeping in mind that the biomass carbonization furnace cost is closely tied to its processing capacity.

Large-scale continuous carbonization furnace

Large-scale continuous carbonization furnace

Established brands often price their charcoal carbonization furnaces higher due to their strong market reputation, mature R&D capabilities, and comprehensive after-sales support. Reliable manufacturers not only deliver high-quality equipment but also provide end-to-end services, including installation, debugging, operator training, and troubleshooting, ensuring smooth and worry-free operations.

DOING has built a full-process and global service system.branches and strategic partnerships in countries like Nigeria, ensuring a quick response to customer needs for carbonization equipment installation. We can offer services to customers from worldwide, such as India, Brazial, Russia, India, Spain, Indonesia, Vietnam, Thailand, America, Chile, Canada, Nigeria, South Africa, etc. O ur comprehensive service includes installation manuals, online guidance, on-site construction, worker training, and a one-year equipment warranty. Additionally, we provide 24/7 remote monitoring and troubleshooting support to ensure rapid delivery of replacement equipment, minimizing potential downtime.

DOING charcoal making machine service team

DOING charcoal making machine service team

In comparison, lower-priced options from lesser-known brands may involve minimal upfront costs but often lack reliable after-sales service, potentially disrupting long-term production.

The price of charcoal carbonization furnaces are influenced by multiple factors, and there is no one-size-fits-all answer. As a professional manufacturer of continuous carbonization furnaces, DOING offers equipment made from premium materials, advanced technology, and a wide range of models to meet diverse client needs. If you would like a specific quotation for a charcoal carbonization furnace or have procurement requirements, please feel free to contact us. We are ready to provide professional solutions and detailed pricing information!