1.Copper wire recycled machine

Copper wire recycled machine

There is a market for recycled copper wire. Metal recycling and salvage companies across the province buy old copper wire and send it for re-refining or smelting. Recycling means less new material is needed for manufacturing and, at the same time, it means less copper is being dumped into our landfills.

However, some of the old copper wire is covered in insulation which must be removed before the copper wire can be recycled.

The insulation can be safely removed by a mechanical process that cuts the insulation and strips it from the copper wire or by processing the insulated wire in an approved incinerator.

We DOING Company as a leading manufacturer in China has specialized in copper wire recycled machine .

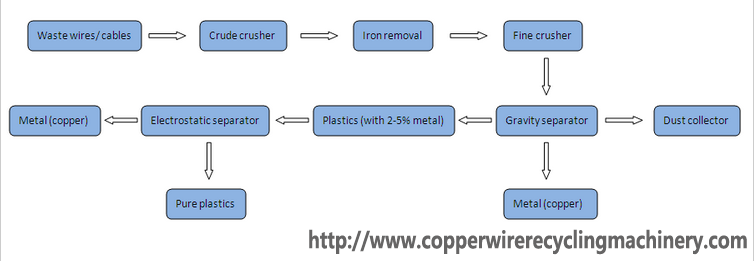

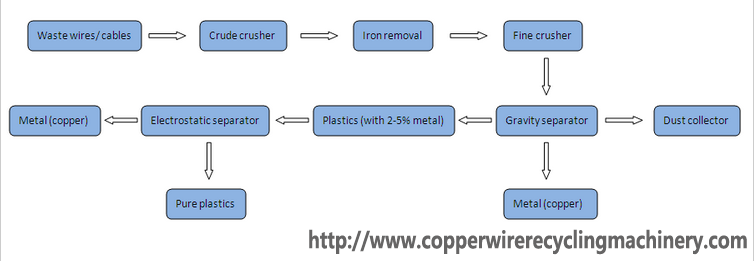

2.Copper wire recycled machine process

Copper wire recycled machine process

1.We directly put waste copper wire in to copper wire recycled machine,waste copper wire and used cale is cut into granules

2.Then granules are sent to vibration device for separation ,through wind and virbration ,the coppe and plastic are separated

3.Then pure copper come from one side and pure plastic come out form the other side

4.we can collect pyre copper and plastic ,the separatid rate can reach 99.9%

3. The advantage of Copper wire recycled machine

1.only 2 workers to operate the whole system

2.Cable diameter under 25mm can be processed

3.Purity of copper over 99%

4.No pollution

5.Skid mounted available

6.The whole system is controlled by PLC

4. The advantage of Copper wire recycled machine

|

Item |

Model |

Capacity(kg/h) |

Power(Kw) |

Size (m)(L*W*H) |

Weight(T) |

Remark |

|

1 |

DY-400 |

100-200 |

28.5 |

3.5×1.5×3.0 |

1.8 |

|

|

2 |

DY-600 |

300-500 |

36.5 |

4.0×1.7×3.0 |

3.0 |

|

|

3 |

DY-800 |

500-800 |

90.0 |

4.5×1.5×4.2 |

7.7 |

Doubling crushing system |

|

4 |

DY-1000 |

800-1000 |

104.2 |

4.8×1.8×4.2 |

9.4 |

Doubling crushing system |