WhatsApp

WhatsApp

DOING HOLDINGS

Environmental Protection Equipment Manufacturer

Environmental Protection Equipment Manufacturer

Scrap copper wire recycling machine

Scrap copper wire recycling machine

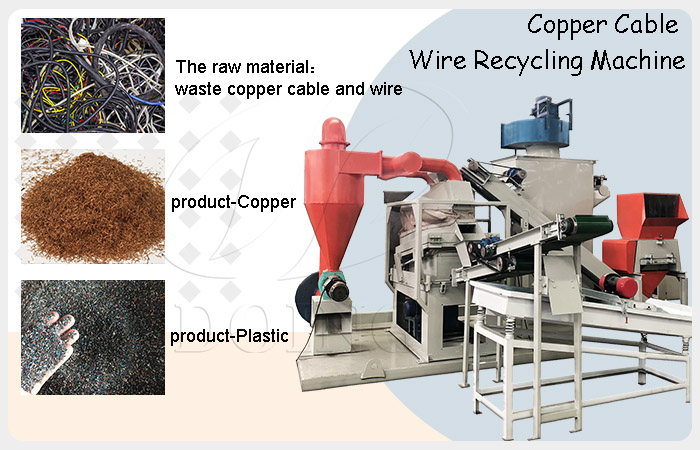

As the name suggests, scrap copper wire recycling machine is a machine for processing scrap copper wires to recycle copper and plastic. Due to the separated copper looks like rice, it is also called copper wire granulator machine.

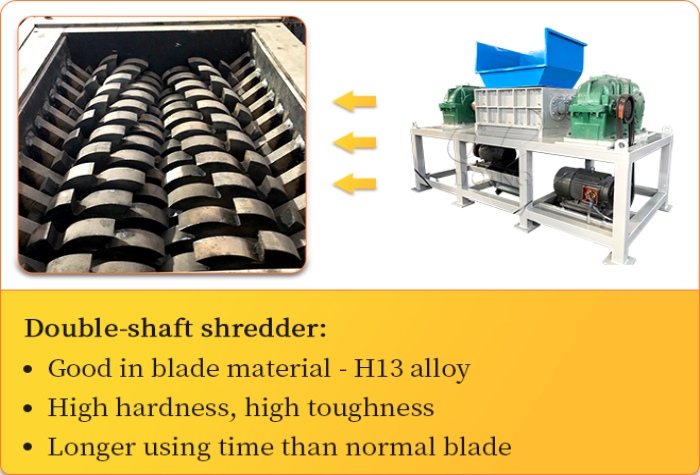

1. Double-shaft shredder

Double-shaft shredder

Double-shaft shredder

Double-shaft shredder is used to preprocess the scrap copper wires, to shred copper wires into small pieces and cut off the plugs on the copper wires. It is made of H-13 alloy, which has high hardness and toughness, and can be used for a long time than other shredders.

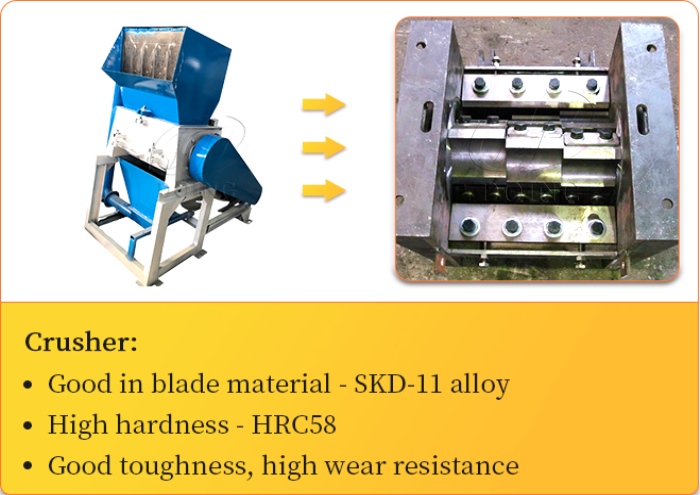

2. Blade crusher

Blade crusher

Blade crusher

Blade crusher can crush the small copper wire pieces into small particles. It is made of SKD-11 alloy, which makes the crusher has high hardness of HRC58, good toughness and high wear resistance.

3. Air separator

Air separator

Air separator

Air separator is used to separate copper from plastic according to their different density via wind and vibration. The separating rate can reach to 97%-98%.

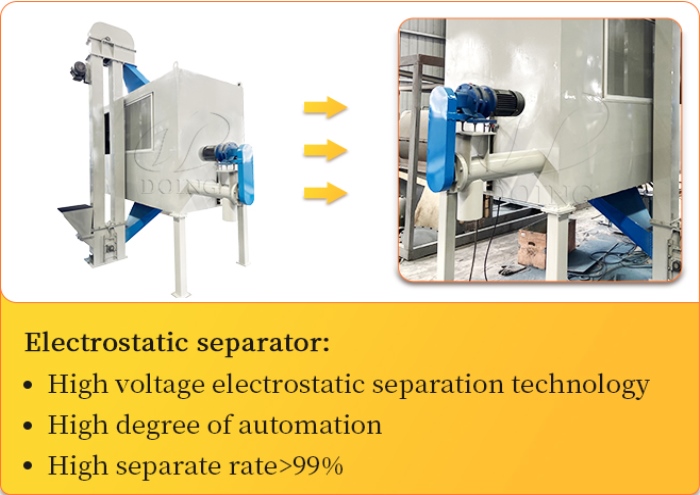

4. Electrostatic separator

Electrostatic separator

Electrostatic separator

Electrostatic separator adopts a high voltage electrostatic separation technology to separate fine copper in the plastic with the separating rate of 99%. In a closed high temperature magnetic field, copper is easily to be separated from plastic due to their different conductivity.

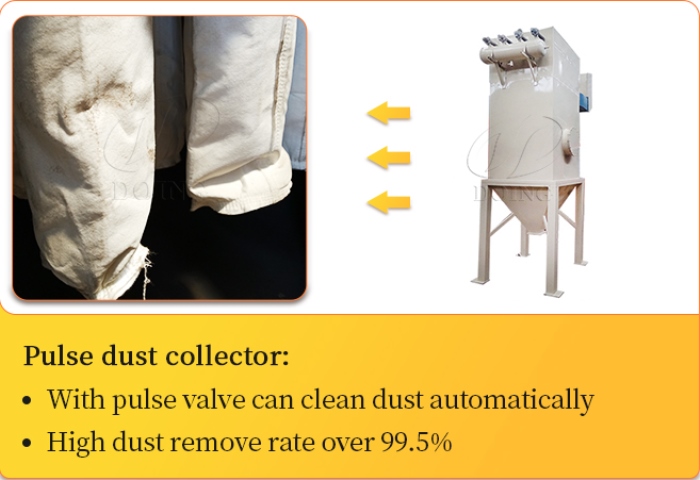

5. Dust removal system

Pulse dust removal system

Pulse dust removal system

Since there is a lot of dust and other magazines on the scrap copper wires, dust removal system is needed. Common dust removal system includes pulse dust removal, cyclone dust removal and bag dust removal system.

The whole working process of scrap copper wire recycling machine includes shredding, iron removal, crushing, air separation, line-vibrating screen, electrostatic separation and dust removal. The following 3D working video can help you get a better understanding.

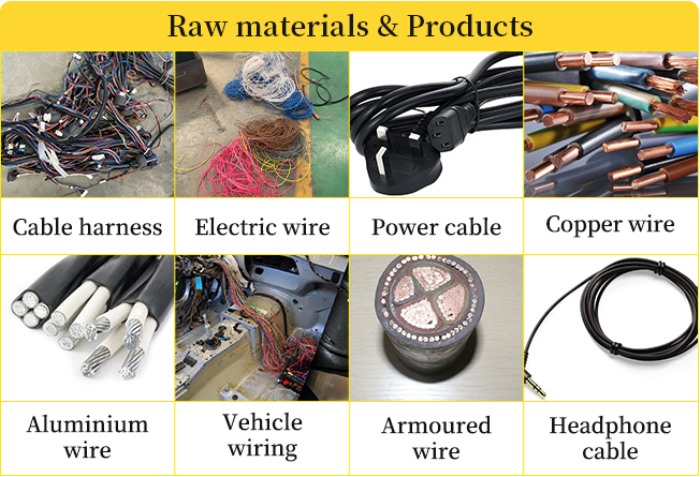

Different waste cable wires

Different waste cable wires

Scrap copper wire recycling machine can handle nearly all the waste wires you have seen, communication wires, household wires, car wires, computer wires, buried cables, armored cables, etc. whether copper wire or aluminum wire.

1. Copper

The first final product of scrap copper wire recycling machine is copper with high purity and good quality, which can be sold with a considerable profit in the metal trading market, or it can be made new products, like copper ingots, copper electrolysis, and then sell.

Final products

Final products

2. Plastic

The other final product is plastic. As for plastic, it can be sold directly as well. Or you can pellet the plastic into other products, like wire cover, tray, blister sheet, mouse, keyboard, etc.

[ Recommended reading: Investment-profit analysis of copper wire granulator machine ]

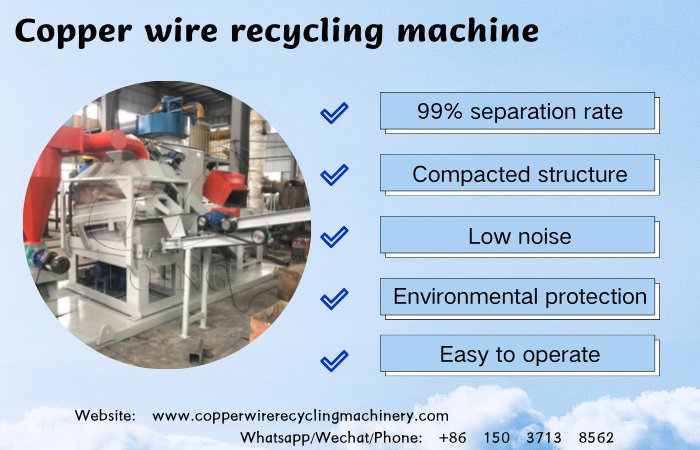

1. Only 1-2 workers need to operate, save labor, occupy less land, and invest less;

2. PLC control system, easy to operate, smooth performance;

3. Double separation process, high separating rate of 99%;

Feature of scrap copper wire recycling machine

Feature of scrap copper wire recycling machine

4. Dry type physical separation, no water, no dust, no fire, and no gas to environment.

5. Large handling capacity, suitable for large scale production.

Henan Doing is the experts in the filed of e-waste recycling. We can not only provide scrap copper wire recycling machine, but also PCB recycling machine and radiator recycling machine. Before delivery, all of our machine will use the material tests that customers need to deal with to ensure that the performance and production of the production line meet the customer's requirements. We sincerely invite customers to come to the site for final testing.